It’s imperative that pharmaceutical products contain exactly the right level of active ingredient and that they interact in the right way with the body. On the medical manufacturing side, all medical devices and implants must be made from the specified alloy and coated with the correct thickness of biocompatible material to ensure acceptance by the body. Also, any tools used in manufacture must be produced from the right alloy, and manufacturers will need to verify this.

Many different analysis techniques play a part in the medical and pharmaceutical sector. Thermal analysis is a powerful technique in characterizing and evaluating pharmaceutical products, both in development and production. Laser Induced Breakdown Spectroscopy (LIBS) handheld analyzers make alloy identification of tools and equipment fast and simple. Powerful and accurate OES is used for medical device melt control, whereas XRF is the technique to choose for coating thickness and composition verification.

The NEXTA DSC series delivers world-class sensitivity and baseline flatness that is so essential when evaluating and developing pharmaceutical products. Suitable for thermal characterization and evaluation of crystallization effects, the NEXTA DSC is compatible with Hitachi’s unique RealView system, allowing you to see effects such as crystal flow alongside your thermal analysis. Our thermal analyzers also come with software that conforms with 21CRF Part 11 and includes all modules as standard, allowing for advanced analysis right out of the box.

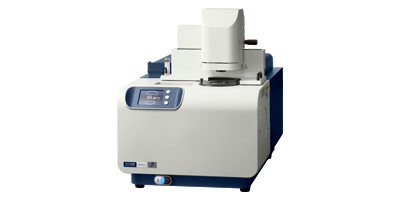

The NEXTA STA delivers TGA and advanced DSC analysis, offering world-class baseline performance for accuracy and precision. Superior balance control technology means the tiniest of reactions can be measured. The thermogravimetric element is useful for observing the thermal decomposition of medicines to determine the amount of active component. Hitachi’s RealView camera observation system is compatible with the NEXTA STA, giving you the complete picture of your sample during a thermal analysis routine and, like all Hitachi thermal analyzers, the NEXTA STA conforms to 21CRF Part 11.

Handheld XRF like Hitachi’s X-MET8000 provides fast and cost-effective non-destructive verification, testing and screening for compliance with RoHS regulations and alloy identification. The X-MET is able to verify compliance at all stages of manufacturing including for substances prohibited by RoHS like lead (Pb), mercury (Hg), chromium (Cr), bromine (Br) and cadmium (Cd) in medical devices.

The Vulcan is a handheld LIBS analyzer that’s designed for rapid and accurate alloy identification. With grade identification completed in seconds, this point and shoot design is ideal for material verification of dies and punches used in the manufacture of pharmaceutical products. Vulcan is very simple to use and will automatically transfer results to the cloud for secure data storage.

The OE Series of spark spectrometers can detect the complete spectrum of elements in metal. Superior detection technology delivers the low detection limits found in melts for medical devices and implants. This range excels at controlling main, residual, tramp and trace elements and delivers the level of performance usually only seen in larger and more expensive OES analyzers.

We have a range of benchtop XRF analyzers that are designed specifically for coating thickness verification. With the ability to non-destructively measure very thin layers, or even multi-layer coatings, our range of instruments are accurate, precise, reliable, and durable enough to withstand constant use. Automated features and an intuitive software interface make analysis fast and easy and reduces the likelihood of human error.

Find out more about our range of analyzers and how they can be used for specific applications within the pharmaceutical and medical field by downloading the documents below:

For more information on the best instrument for the quality control within pharmaceutical or medical markets, get in touch to speak with one of our experts.