DSC is used to measure heat flow for material characterization by providing thermal properties such as melting point, glass transition and crystallization. DSC instruments are used both in quality control and R&D across a wide range of industries including polymers, pharma, electronics, chemical, academia, oil and gas, food, and metals.

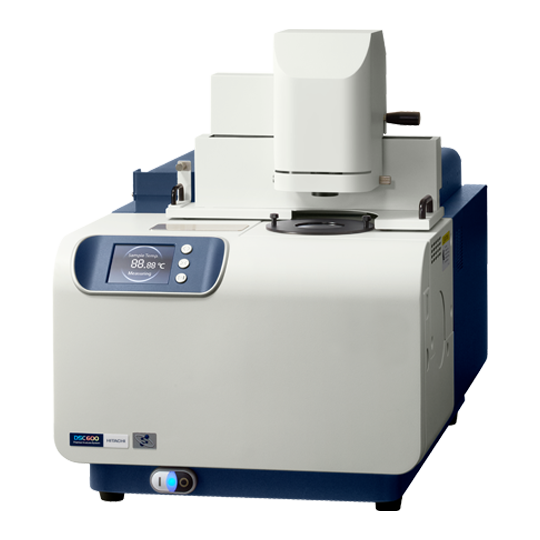

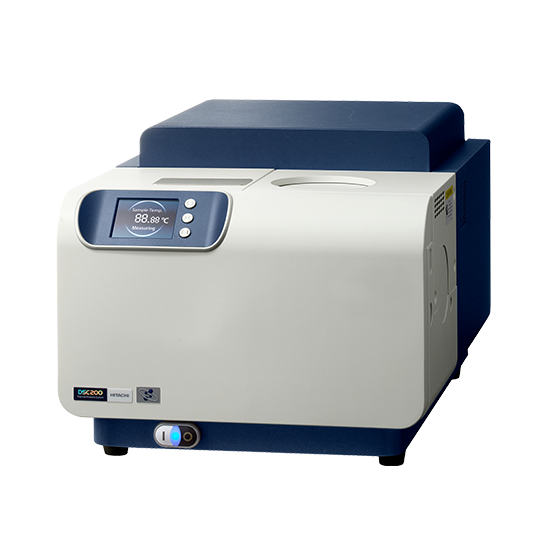

Our NEXTA DSC Series instruments offer world-class sensitivity and baseline reproducibility, delivering more accurate testing and the ability to evaluate even the smallest thermal events. Our innovative Real View® camera system provides real-time observation during measurement. The DSC200 offers leading technology for routine applications without limitations and ideal for a wide variety of applications. The DSC600 is purpose designed to meet the most advanced materials development and failure analysis thanks to its sensitivity and resolution, especially within applied research.

Request more informationThe Real View® camera system integrates seamlessly with NEXTA DSC Series to observe changes in the sample status during analysis in real-time. Images reveal changes in sample shape, size, colour, and other properties. The images can be recorded and are automatically linked to the thermal data by timestamp. You can also integrate Real View® with the Auto Sampler to monitor changes to your samples while automatically analyzing several samples at once.

Upgrade your DSC analytical capabilities with high-resolution imaging for crystal orientation, multilayer film quality control, fish-eye contamination detection, and failure analysis. Explore sample anisotropy and crystal orientation with a 20-megapixel camera, offering 50-fold digital zoom and a pixel resolution of 1.2µm. Controlled polarization technology and dedicated image processing ensure detailed observations for precise structural analysis.

Automate the entry of measurement conditions with a barcode reader, mass upload of up to 5000 sample information data points like name, method file, lot number and export all your data including test results into CSV, Excel and text formats to make data management easier and more reliable.

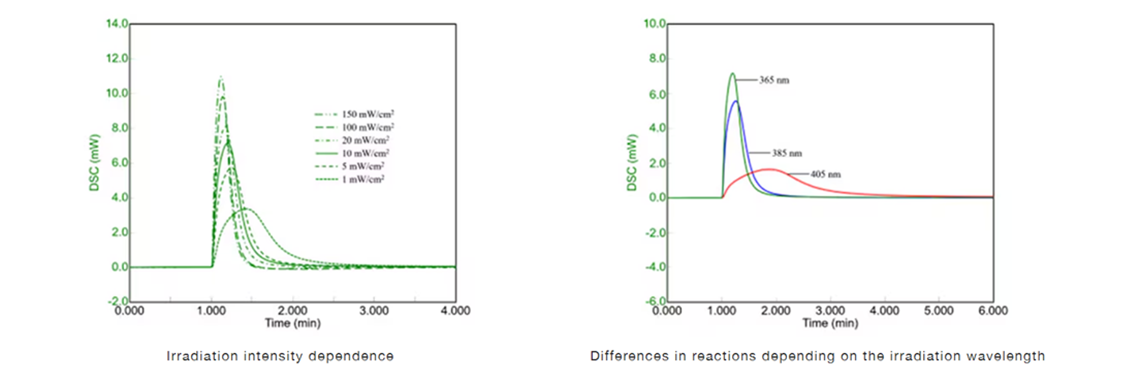

The PDC-8 / PDC-8LED accessories for the NEXTA DSC make it easy to optimize your UV curing process.

Measure the heat generated by the exothermic UV reaction and track the curing time under different wavelengths and irradiation levels. After curing, a standard DSC scan reveals changes in material properties. With a high-output UV light source and wavelength-selective filters, the UV curing process can be fine-tuned with precision.

PDC-8 | PDC-8LED | |

UV Light Source | Hg-Xe Lamp | LED |

Temperature Range | Room temperature ~150°C when using PDC*

| Room temperature ~150°C when using PDC* |

Wavelength Range | 240–550 nm | N/A |

| Wavelength Selection | 254, 313, 365, 405, 436 nm | 365, 385, 395, 405 nm |

Maximum Irradiation Intensity | 500 mW/cm² | 150 mW/cm² |

| Irradiation Control | Can be linked to temperature programs | Can be linked to temperature programs |

DSC200 | DSC600 | |

Heat Flow Measurement Method | Heat flux with centric heat flow | Heat Flow Measurement Method: Heat flux with centric heat flow and 3 thermocouples |

Time Constant (resolution) | 6.5 seconds or better | 3 seconds or better |

RMS noise / Sensitivity | 0.1 µW / 0.2 µW | 0.05 µW / 0.1 µW |

Temperature Range | -150 to 725°C | |

Programmable Heating/Cooling Rate | 0.01 ~ 100˚C/min | |

Temperature Precision | +/- 0.01°C | |

Temperature Accuracy | +/- 0.05°C | |

Calorimetric Precision | +/- 0.05% | |

Calorimetric Accuracy | +/- 0.4% | |

Baseline Stability | +/-5µW | |

Real View® Camera System | Optional | |

We’d love to hear from you! Contact us if you would like a quote, demo, or if you have a question.