In the complex fields of material analysis, where precision is key, consumables and accessories play a vital role. These small parts are crucial for getting accurate results, generating cost savings, and keeping operators safe. From shielding radiation to maintaining instrument health, each consumable has a part to play in your analytical journey.

Some accessories are essential for operator safety, especially for those working with handheld X-ray analyzers. A light radiation shield, for example, is specifically designed to reduce scattered radiation when analyzing light alloys like Aluminum. This shield significantly improves operator safety, tackling the unique challenges tied to portable X-ray analysis and lightweight materials.

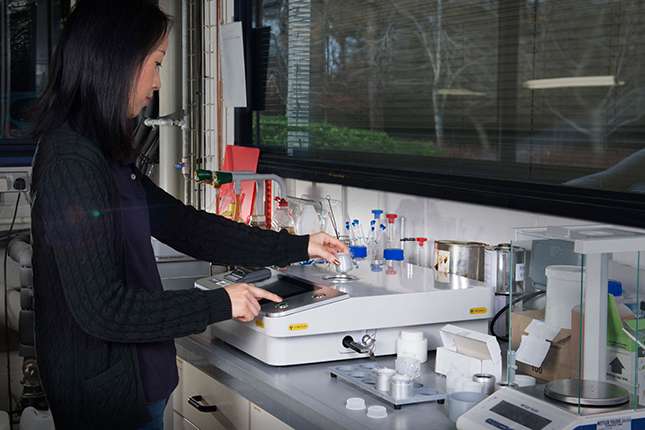

Stands simplify sample handling by providing stability and consistent sample placement, ensuring instruments stay in place, and experiments run smoothly, contributing to on-site safety.

Ensuring consistent and precise results is crucial in any analytical process. If an application is developed with specific consumables, optimal outcomes are guaranteed by consistently using the same items. Customers should rely on genuine accessories and consumables to not only fine-tune their systems but also achieve results with precision and accuracy.

Consider XRF testing of paper or thin films. Results will vary if the samples aren’t flat or differ in size. By equipping users with simple and safe tools to cut reproducible disks, and holders designed to keep the sample surface flat during analysis, operators can be confident they will achieve results they can trust.

Good thermal analysis results also rely on quality consumables. If you are looking for a weak glass transition or a minute weight loss, you must use sample pans which will give you consistent and reliable results with your instrument.

Keeping your instrument in good shape and avoiding repair costs matters and consumables support this. Take the safety window for benchtop XRF instruments, for example. It is a protective “shield” which is placed under the sample cup during analysis, stopping leaks and saving your instrument from possible contamination and damage. Its simplicity makes it an indispensable tool, averting costly repairs and preserving the efficiency of your analytical instrument.

Consideration for the environment and cost-effectiveness extends to the reusability of certain consumables. For instance, Aluminum sample cup outers are designed for long-term use, reducing plastic waste, and providing a sustainable solution. This design not only contributes to environmental conservation but also ensures minimal impact on your operational costs.

Some thermal analysis pans are also re-useable. Platinum crucibles are designed for multiple uses, and their longevity can be extended, especially with the use of a reformer tool to maintain their original shape.

In Optical Emission Spectroscopy (OES), consumables like brushes and electrodes are vital for maintaining peak equipment performance. Regular replacement is crucial to prevent cross-contamination, ensuring accurate analyses. This practice is essential in industries where the slightest contamination can lead to errors or safety concerns, guaranteeing precision and reliability in every analysis.

Precision begins with the choices you make, down to the consumables you trust. Whatever analysis method you are employing, they go beyond just being components; they significantly impact precision, safety, and overall analytical success.

For more information on the consumables Hitachi High-tech offers click here.

Our service team is dedicated to keeping you running. Discover more about how we ensure your operations run smoothly.