Materials are coated or plated to improve functional behavior and increase life expectancy. The thickness of the coating must fall within the given specification range. If the plating is too thin, then the final component may fail prematurely in the field due to corrosion, wear or in the case of electronics, poor electrical contact. Coatings that are too thick can affect the way complex components such as engine parts fit together. For coatings that are decorative, achieving the right thickness is important to give the finished product the right appearance – if this is wrong then the component will need to be reworked or scrapped.

The challenge is how to accurately and reliably measure coating thickness on finished components. There may be several layers to analyze, and the measurement process must not damage or cosmetically affect the component in any way. This is where XRF analyzers and electromagnetic contact gauges stand out – reliable, accurate and non-destructive, these analytical techniques can deliver results in seconds, allowing you to take critical measurements on coated components or finished assemblies.

The FT200 Series XRF coatings analyzers are designed to simplify and accelerate testing of components and assemblies making it easier to measure more parts in less time. With features such as Find My Part™ smart recognition, automated sample focusing and a wide view camera, the FT230 and FT210 reduce set up time and user error to increase throughput and productivity. Let your XRF make decisions for you.

A versatile benchtop XRF designed to analyze samples of a wide range of shapes and sizes. The X-Strata920 can be configured to accommodate very different samples, including electronics, connectors, decorative items and electroplated or galvanized components. With six collimators included and a choice of detector type, this instrument can be tailored to your specific application.

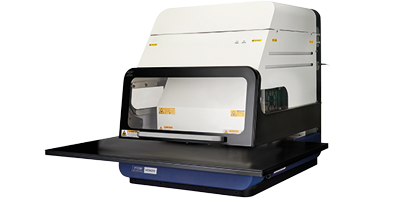

The FT110A is a benchtop XRF analyzer designed for high-throughput production. A powerful X-ray source, a large sample chamber and automated positioning all help to increase throughput while maintaining high accuracy and performance. With the capability of measuring up to four layers at once, plus the substate, the FT110A is a powerful asset to high-volume quality control.

The FT160 is a high-performance benchtop XRF analyzer designed to meet the challenges of taking highly accurate coating thickness measurements on the tiny features found on today’s electronics components. Polycapillary optics and advanced detector technology allows you to measure nanometer-scale coatings on features smaller than 50 µm.

This handheld XRF analyzer provides quick and non-destructive at-line testing to measure coating thickness and weight. Use it also for heavy and bulk items when it’s not practical to use a benchtop instrument.

Our digital coating thickness gauges range from simple handheld instruments to high-end benchtop models for fast, non-destructive testing of electroplated and galvanized coatings over ferrous substrates.

Our range of thickness gauges for paint and powder coatings can also measure anodizing thickness on aluminum. They can measure a large range of protective coatings, including polymers, epoxy, resin and rubber.

We offer a range of PCB copper thickness gauges for copper foil and laminate thickness, surface copper thickness and through-hole copper thickness. Ideal for incoming inspection and process control, you can choose between five different models.

Watch how Hitachi analyzers can make the difference in electronics manufacturing and plating shops:

Take a look at our library of webinars available to watch on demand for the electronics and metal finishing industries.

Find out more about our XRF analyzers and electromagnetic thickness gauges and how they can help you meet stringent quality targets.

For more information on the best instrument for your coating application, get in touch to speak with one of our experts.

Contact Us