Functional and decorative metal finishing coatings play an important part in the performance, longevity and appearance of many components. Ensuring plating is the right thickness is a key part of the quality control process within metal finishing and plating shops. If the coating is too thin, then the part may corrode, have a poor appearance, or have other performance issues. In some cases, a coating that’s too thick can also have detrimental effects, as well as add to the plating costs.

XRF analysis equipment and electromagnetic thickness gauges are non-destructive and will take an accurate measurement without damaging the appearance or integrity of the coated layer or layers. It’s important to choose the right analyzer for the type of coating and substrate and Hitachi offer a range of instruments to meet a variety of applications.

FT200 Series: Small-spot XRF with advanced features for high-volume testing

The FT200 Series XRF coatings analyzers are designed to simplify and accelerate testing of components and assemblies making it easier to measure more parts in less time. With features such as Find My Part™ smart recognition, automated sample focusing and a wide view camera, the FT230 and FT210 reduce set up time and user error to increase throughput and productivity. Let your XRF make decisions for you.

X-Strata920 benchtop XRF for analyzing a wide range of samples

This benchtop XRF is ideal if your plating shop deals with a wide range of samples of varying shape and size. Choose between an SDD or proportional counter model and select from different stage options, including a deep well option for tall samples. Both X-Strata920 models come with up to six collimators for you to optimize the measurement time and accuracy for each analysis.

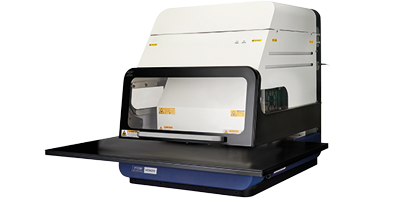

FT110A benchtop XRF for large samples and powerful analysis

The FT110A is an ideal benchtop XRF if you need to analyze large samples, or you would like to load several different samples at once. The large sample stage, powerful X-ray source and automated positioning functionality all speed up the measurement process, and the rugged and durable design mean that this powerful analyzer can support your production round the clock.

Suitable for automotive / aerospace components, appliances, general industrial parts and architectural pieces, our range of thickness gauges support quality control in your electroplating and galvanizing operations.

Easy to use by high-volume manufacturers, body shops and hobbyists alike, our range of paint thickness gauges helps to ensure a consistent coating thickness on ferrous and non-ferrous substates.

This handheld XRF analyzer provides quick and non-destructive at-line testing to measure coating thickness, coating weight and plating bath solutions. Use it also for heavy and bulk items when it’s not practical to use a benchtop instrument.

Watch how Hitachi analyzers can make the difference for general metal finishing within plating shops.

Find out more about our XRF analyzers and electromagnetic thickness gauges and how they can help you meet stringent metal finishing quality targets.

For more information on the best instrument for your metal finishing coating application, get in touch to speak with one of our experts.

Contact Us