Microspot XRF coating thickness and materials analyzers for rapid quality control and validation testing, making it easy to get the right results in seconds.

Coating measurement and materials analysis based on micro X-ray fluorescence (XRF) is a widely accepted and industry-proven analytical technique, offering easy-to-use, fast and non-destructive analysis, requiring little to no sample preparation, capable of analysing solids or liquids over a wide element range from 13Al to 92U on the periodic table.

Request pricing or a demoThe ability to control finishing processes determines the pitch, reliability and shelf life of boards. Measure electroless nickel (EN, NiP) plating thickness and composition according to IPC-4556 and IPC-4552B. Hitachi High-Tech Micro XRF products enable you to maintain your operations in tight tolerance to ensure high quality and avoid costly re-work.

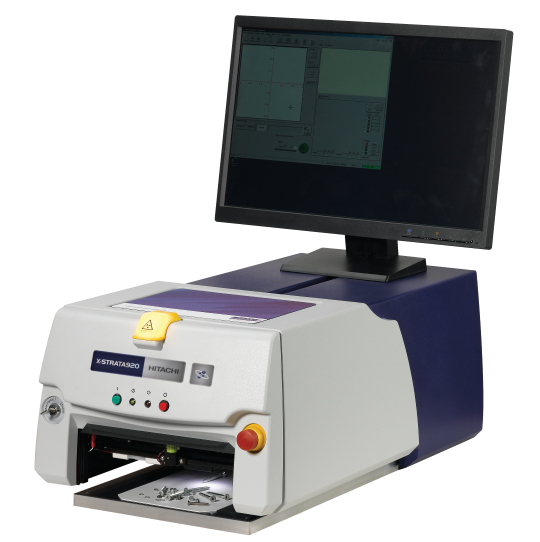

Components must be plated within specification in order to provide the desired electrical, mechanical and environmental properties. Measure small features or continuous strips using the slotted chamber of the X-Strata series products to control top, intermediate and strike layers for lead frames (leadframes), connector pins, wire and terminations.

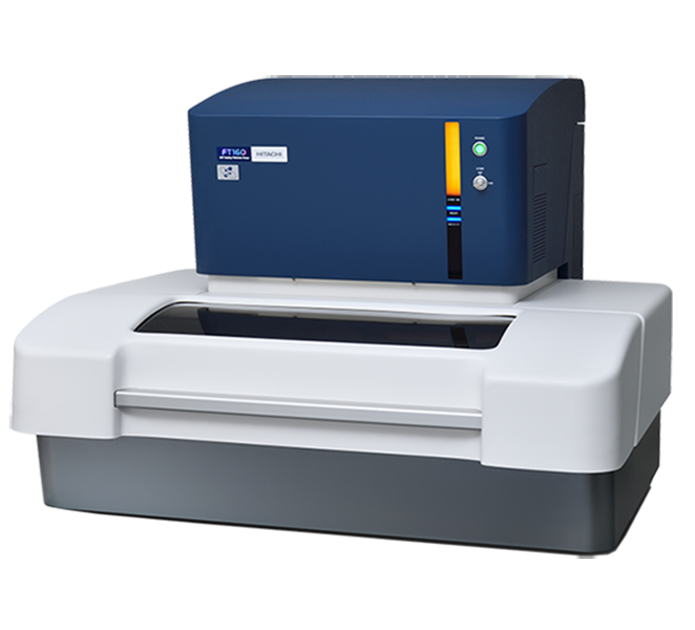

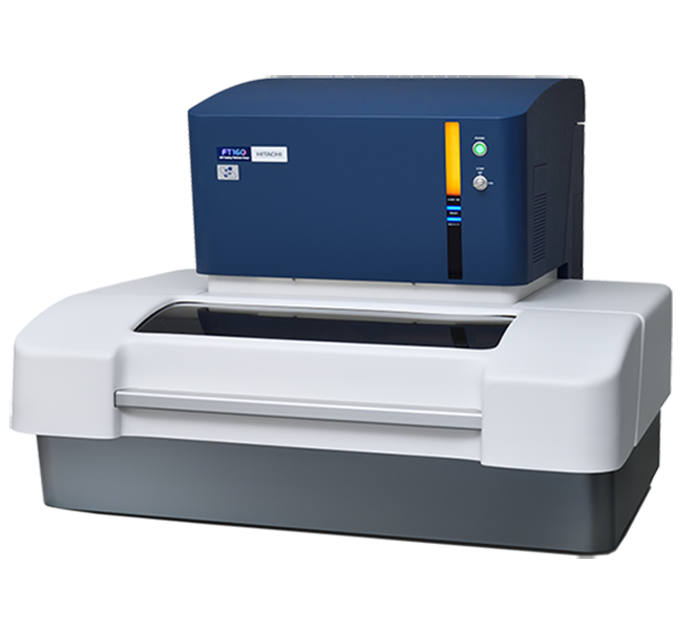

Semiconductors are becoming increasingly miniaturized and complex, requiring analytical equipment to measure thin films in small areas. Hitachi High-Tech benchtop analyzers are designed to provide high precision analysis and reproducible sample positioning for demanding applications.

Combining sourced and locally manufactured components to build a final assembly or product involves many test points, from incoming inspection to at-line process control to final quality control. Our benchtop XRF products allow you to analyze components, solder and finishes throughout the facility, ensuring quality at every step.

The demand for renewable energy continues to increase, with photovoltaics playing an important role in harnessing the power of the sun. The ability to collect this energy efficiently is in part determined by the quality of the thin film solar cells. Ensure these cells are plated accurately and consistently with microspot XRF to achieve maximum efficiency.

Working with a complex, global supply chain it is critical to trust and verify materials received from suppliers. Use our XRF technology to validate incoming shipments comply with regulations such as RoHS and ELV following IEC 62321 methodology, and ensure high reliability coatings are applied for aerospace and military applications.

| X-Strata920 | X-Strata920 | FT110A | FT160 | |

| ENIG | ★★☆ | ★★★ | ★★☆ | ★★★ |

| ENEPIG | ★★☆ | ★★★ | ★★☆ | ★★★ |

| Electroless nickel thickness and composition (IPC 4556, IPC 4552) | N/A | ★★☆ | N/A | ★★★ |

| Electroless nickel thickness | ★★☆ | ★★★ | ★★☆ | ★★★ |

| Immersion Ag | ★★☆ | ★★★ | ★★☆ | ★★★ |

| Immersion Sn | ★★☆ | ★★★ | ★★☆ | ★★★ |

| HASL | ★★☆ | ★★★ | ★★☆ | ★★★ |

| Pb-free solder (eg. SAC) | ★☆☆ | ★★☆ | ★☆☆ | ★★★ |

| CIGS | N/A | ★★☆ | N/A | ★★★ |

| CdTe | N/A | ★★☆ | N/A | ★★★ |

| Thin film analysis at nm-scale | N/A | ★★☆ | N/A | ★★★ |

| Multi-layer analysis | ★★☆ | ★★★ | ★★☆ | ★★★ |

| IEC 62321 RoHS screening | N/A | N/A | N/A | N/A |

| Measure features < 50 µm | N/A | N/A | N/A | ★★★ |

| Pattern recognition software | N/A | N/A | ★★★ | ★★★ |

| Elemental mapping | N/A | N/A | N/A | N/A |

Verify the thickness and chemistry of the applied coatings to ensure product functionality and life-span in harsh environments. Handle small fasteners or large assemblies with ease.

Prevent product failure by ensuring coating thickness and uniformity of critical components operating in abrasive environments. Complex shapes, thin or thick coatings and finished goods can all be measured.

When the goal is to achieve a flawless finish, quality control throughout the production process is critical. With our range of test equipment, you can reliably inspect base materials, test intermediate and top layers.

Surface treatments for parts operating in the most extreme conditions must be controlled within tight tolerances. Ensure coatings specifications are met to prevent product recalls and potentially catastrophic failures.

| X-Strata920 | X-Strata920 | FT110A | FT160 | |

| Zn / Fe, Fe alloys Cr / Fe, Fe alloys Ni / Fe, Fe alloys | ★★☆ | ★★★ | ★★☆ | ★★★ |

| ZnNi / Fe, Fe alloys ZnSn / Fe, Fe alloys | ★★☆ | ★★★ | ★★☆ | ★★★ |

| NiP / Fe NiP / Cu NiP / Al | ★★☆ (Thickness only) | ★★☆ (Thickness and composition) | ★★☆ (Thickness only) | ★★★ (Thickness and composition) |

| Ag / Cu Sn / Cu | ★★☆ | ★★★ | ★★☆ | ★★★ |

| Cr / Ni / Cu / ABS | ★★☆ | ★★★ | ★★☆ | ★★★ |

| Au / Pd / Ni /CuZn | ★★☆ | ★★★ | ★★☆ | ★★★ |

| WC / Fe, Fe alloys TiN / Fe, Fe alloys | ★★☆ | ★★★ | ★★☆ | ★★★ |

| Thin film analysis at nm-scale | N/A | ★★☆ | N/A | ★★★ |

| Multi-layer analysis | ★★☆ | ★★★ | ★★☆ | ★★★ |

| IEC 62321 RoHS screening | N/A | N/A | N/A | N/A |

| Distance independent measurement | N/A | N/A | ★★★ | N/A |

| Pattern recognition software | N/A | N/A | ★★★ | N/A |

We’d love to hear from you! Contact us if you would like a quote, demo, or if you have a question.