We have a range of analyzers developed for coating thickness testing and composition measurements. Our XRF instruments are engineered for fast and accurate coating analysis, with benchtop and handheld instruments available for microspot XRF analysis and thin film thickness measurements. Beyond coating thickness and composition testing, XRF analysis is the technology to choose for plating bath chemistry analysis, and our instruments include features that make this essential test easy.

We also have a range of coating thickness gauges for rapid coating thickness measurements on metallic substrates. With eddy current and magnetic thickness probes available, again, you have the choice between handheld thickness gauges and benchtop instruments for precise coatings analysis.

All our instruments contain high specification Hitachi detection technology and are built to withstand constant use.

Request Pricing or Demo

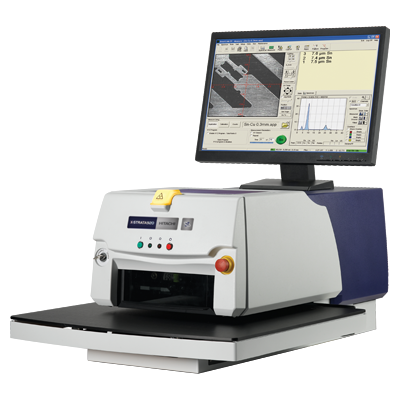

X-Strata920: Flexible fit for samples of any shape

Designed to analyze samples of a wide variety of shapes and sizes, the X-Strata920 is ideal for many applications, including PCB surface finishes.

Download brochure

X-Strata920 SDD: Flexibility with high resolution detector

The X-Strata920 SDD offers the same flexibility as the X-Strata920, but with a silicon drift detector (SDD) for analyzing complex and thinner coatings.

Download brochure

FT110A: Powerful XRF for larger boards

Designed to accommodate large boards, this advanced XRF analyzer is easy to use and delivers fast and accurate results with features built for high productivity.

Download brochure

FT160: Microspot analysis for miniaturized electronics

Designed for microspot and ultra-thin coatings analysis, the FT160’s polycapillary optics and detector technology are optimized for features less than 50 µm.

Download brochure

X-MET8000: Portable XRF analysis

A lightweight and rugged handheld XRF analyzer for rapid, on-the-spot plating thickness measurement, with up to 12 hours of battery life.

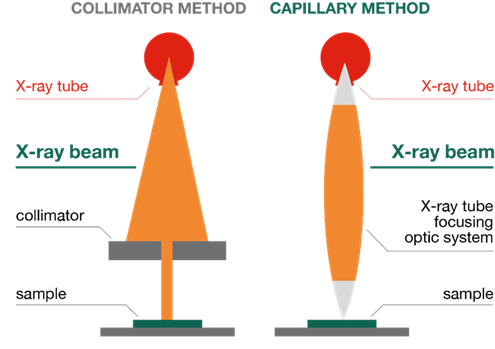

Download brochureFor our XRF instruments, you can choose from two optics configurations: mechanical collimators or polycapillary optics, depending on the size of your features and thickness of the coatings you need to analyze.

Ideal for features down to 100 µm, our analyzers with collimators offer multiple size options for optimized precision and rapid analysis.

For features less than 100 µm and coatings in the nanometer-range, capillary optics are the best choice. For our polycapillary optics XRF instruments, many capillary tubes are clustered together in a tapered configuration. This advanced technology can achieve the smallest spot sizes and direct more X-rays at the board, giving better precision on smaller areas.

Our global experts are on hand to help your business find the coating thickness gauge for your needs.

Benchtop XRF, handheld XRF and electromagnetic gauges for zinc (Zn) coating thickness analysis for hot dip and electrogalvanizing operations.

Choose between XRF for plating thickness and composition, and electromagnetic thickness gauges for rapid measurements of electroplated coatings on a wide range of substrates.

High-performance benchtop XRF instruments designed for coating thickness analysis of metal surface finishes on a wide range of boards, and electromagnetic gauges for surface and thru-hole copper thickness.

Ultra-high precision and accuracy for XRF coating thickness and composition on micro-connectors, lead frames, interconnects and cable connectors.

High-precision XRF analyzers for coating thickness analysis on flip chip packaging and IC substrates. Advanced optics for features smaller than 50 µm.

CMI155/157: Advanced coating thickness measurement on metal substrates

Rapid and reliable inspection of paint, lacquer, and protective coatings on ferrous and non-ferrous substrates.

CMI233: High performance, affordable and rugged design for reliable measurements

Diverse handheld coating thickness gauge with the accuracy of a benchtop instrument.

CMI243: Advanced metallic coating measurement

Accurate measurement of electroplating and galvanizing for plated metals over ferrous substrates.

CMI255/257: Dual technology gauge for quality assurance of coating thickness

Reliable and advanced metal coating thickness for quality assurance of paint, lacquer, zinc and other protective coatings on ferrous and non-ferrous substrates.

CMI730: Benchtop gauge for advanced plating process control

Versatile benchtop gauge for electroplating, galvanizing, anodizing and paint coating thickness measurements.

CMI95M: Rapid and reliable copper foil and laminate thickness measurement

Measure foil or laminate thickness on PCBs between 1/8 to 4.0 oz/ft2 (5-140 μm) in less than 1 second.

CMI165: Reliable and non-destructive analysis regardless of copper (Cu) temperature

Unique temperature-compensated surface and trace copper (Cu) thickness measurement.

CMI511: Rapid measurement of thru-hole copper (Cu) thickness at any temperature

Temperature compensation allows for fast measurement of plated thru-hole copper (Cu) thickness prior to, and after, etching.

CMI563: Microresistance technology for accurate measurement of copper (Cu)

Advanced surface copper (Cu) measurement on single, double-sided or multi-layer PCB

CMI760: Dual technology for multiple PCB copper (Cu) applications

Dual eddy current and microresistance technology enables you to test foil, laminate, surface, traces and thru-hole copper (Cu) with a single device.