We provide a range of instruments designed for zinc (Zn) coating thickness analysis for hot dip (HDG) and electrogalvanizing operations. Choose from a range of analysis technologies, including benchtop XRF, handheld XRF and electromagnetic gauges. The best type of analyzer for your situation will depend on the accuracy and precision you need, and the type of galvanized components you have to check.

Request Pricing or Demo

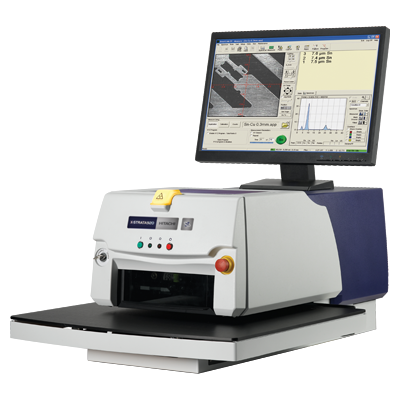

X-Strata920: Flexible fit for samples of any shape

Designed to analyze samples of a wide variety of shapes and sizes, the X-Strata920 is ideal for many applications, including galvanized metal finishes.

Download brochure

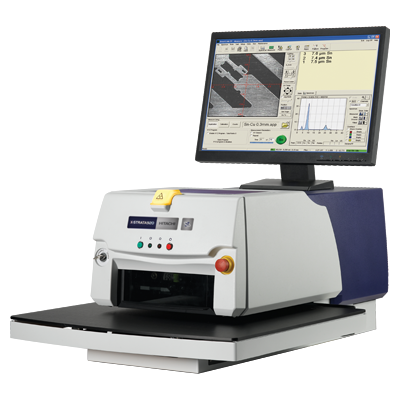

X-Strata920 SDD: Flexibility with high resolution detector

The X-Strata920 SDD offers the same flexibility as the X-Strata920, but with a silicon drift detector (SDD) for analyzing complex and thinner coatings.

Download brochure

FT110A: Powerful XRF for larger substrates

Designed to accommodate larger substrates, this advanced XRF analyzer is easy to use and delivers fast and accurate results with features built for high productivity.

Download brochure

X-MET8000: Portable XRF analysis

A lightweight and rugged handheld XRF analyzer for rapid, on-the-spot plating thickness measurement, with up to 12 hours of battery life.

Download brochure- Benchtop XRF allows small spot analysis to reach tight areas like the head or between threads of screws, bolts and other fasteners

- Handheld XRF provides the accuracy and precision of a benchtop XRF in a portable device to measure large parts like structural steel and lamp posts

- Verify metal substrate chemistry and grade before plating

- Measure plating bath chemistry to determine composition of main elements in bath so you can make adjustments as needed.

| X-Strata920 | X-Strata920 | FT110A | X-MET8000 High resolution SDD | |

| Zn plating | ★★★ | ★★★ | ★★★ | ★★★ |

| ZnNi plating | ★★☆ | ★★★ | ★★☆ | ★★★ |

| Multi-layer analysis | ★★★ | ★★★ | ★★★ | ★★☆ |

| Measure large parts | ★☆☆ | ★☆☆ | ★★☆ | ★★★ |

| Measure parts/features smaller than 1mm | ★★★ | ★★★ | ★★★ | ★☆☆ |

| Measure recessed areas | ★☆☆ | ★☆☆ | ★★★ | ★★☆ |

| Base metal identification | ★★☆ | ★★☆ | ★★☆ | ★★★ |

| Automated focus | N/A | N/A | ★★★ | ★★★ |

| Wide-view camera | N/A | N/A | ★★★ | N/A |

| Pattern recognition | N/A | N/A | ★★★ | N/A |

| Portability | N/A | N/A | N/A | ★★★ |

Our global experts are on hand to help your business find the XRF analyzer for your galvanizing thickness measurement needs.

Eddy current and magnetic induction digital dry film thickness (DFT) gauges quickly measure zinc (Zn) thickness on galvanized parts, as well as other coatings such as paint. Choose from handheld gauges, with the thickness measurement probe built into the gauge body or tethered by a cable, or a benchtop unit that allows you to attach multiple probes for handling several tasks.

CMI155/157: Advanced coating thickness measurement on metal substrates

Rapid and reliable inspection of paint, lacquer, and protective coatings on ferrous and non-ferrous substrates.

CMI233: High performance, affordable and rugged design for reliable measurements

Diverse handheld coating thickness gauge with the accuracy of a benchtop instrument.

CMI243: Advanced metallic coating measurement

Accurate measurement of electroplating and galvanizing for plated metals over ferrous substrates.

CMI255/257: Dual technology gauge for quality assurance of coating thickness

Reliable and advanced metal coating thickness for quality assurance of paint, lacquer, zinc (Zn) and other protective coatings on ferrous and non-ferrous substrates.

CMI730: Benchtop gauge for advanced plating process control

Versatile benchtop gauge for electroplating, galvanizing, anodizing and paint coating thickness measurements.

| Model | CMI155 | CMI157 | CMI255 | CMI257 | CMI233M | CMI233E | CMI233D |

| Gauge | Ferrous / Non-Ferrous | Ferrous / Non-Ferrous | Ferrous / Non-Ferrous | Ferrous / Non-Ferrous | Ferrous | Non-Ferrous | Ferrous / Non-Ferrous |

| Measures on magnetic steel | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Measures on Aluminum | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| Technique | Magnetic induction / Eddy | Magnetic induction / Eddy | Magnetic induction / Eddy | Magnetic induction / Eddy | Magnetic induction | Eddy | Magnetic induction / Eddy |

| Probe | Integrated | Integrated | Integrated | Tethered | Tethered | Tethered | Tethered |

| Probe Replacement | Service | Service | Service | Service | User replaceable | User replaceable | User replaceable |

| Unit Selection | oz or µm | mil or µm | mil or µm | mil or µm | mil or µm | mil or µm | mil or µm |

| Thickness Range - mil | F: 0-80 NF: 0-80 | F: 0-120 | F: 0-140 NF: 0-120 | F: 0-140 | F: 0-140 | NF: 0-60 | F: 0-120 NF: 0-60 |

| Thickness Range - µm | F: 0-2,000 NF: 0-2,000 | F: 0-3,000 NF: 0-3,000 | F: 0-3,500 NF: 0-3,000 | F: 0-3,500 NF: 0-3,000 | F: 0-3,048 | NF: 0-1,524 | F: 0-3,048 NF: 0-1,524 |

| Resolution - mil | 0.1@0-80 | 0.1@0-100 0.2@100-120 | 0.1@0-100 0.2@100-140 | 0.1@0-100 0.2@100-140 | 0.01 | 0.01 | 0.01 |

| Resolution - µm | 1@0-1,000 2@1,000-2,000 | 1@0-1,000 2@1,000-2,500 5@2,500-3,000 | 1@0-1,000 2@1,000-2,500 5@2,500-3,500 | 1@0-1,000 2@1,000-2,500 5@2,500-3,500 | 0.25 | 0.25 | 0.25 |

| Base Re-zero | ✔ | ✔ | ✔ | ✔ | ✔ | ||

| User Calibration | ✔ | ✔ | ✔ | ||||

| Measurement Statistics | ✔ | ✔ | ✔ | ✔ | ✔ |