We’ve been developing, manufacturing, and providing thermal analyzers since commercializing the first calorimeter in 1974. Having worked for almost 50 years in close collaboration with customers to develop solutions to solve their thermal analysis needs, we’re proud to provide an extensive line up of thermal analysis instruments including DSC, STA, TMA and DMA.

Bringing our extensive expertise to benefit your needs, here’s our top five reasons why you should consider Hitachi thermal analyzer:

We’re not a newcomer to the market. Our total installations exceed 20,000 units globally, and we’re known as the best-selling thermal analysis manufacturer* in Japan in 2021. We love working with our customers, listening to their needs, proposing new value and contributing to make our customers businesses grow. Here’s just some of the feedback we’ve received:

*Reference: Scientific Instrument Yearbook 2021 Edition (R&D Co.,Ltd.)

As a member of Hitachi Group, we’ve established and implemented quality standards and product safety design standards which reflect our safety know-how also used by the likes of Hitachi Rail. We also make sure we comply with domestic and overseas laws and regulations to provide customers with high quality and safe products.

All our manufacturing process such as design, manufacturing, inspection, and shipping are performed at our Fuji Oyama plant in Japan. What’s more, our Fuji Oyama plant has achieved substantial carbon neutrality by using electricity being generated from renewable energy since March 2021.

By having all our manufacturing under one roof, we’re able to respond to customer requests easily. With our thermal analysis instruments made in Japan and cleared by Hitachi’s strict quality standard, you get results you can trust even in a development environment. Our robust, sturdy analyzers deliver the reliability you need to keep up and running.

We’ve developed and launched ‘the world’s first’ thermal analysis products like a microcomputer DSC, horizontal differential balance TG/DTA and Real View® camera STA.

In 1970s, the SSC560 series was launched as ‘the world’s first’ DSC with computer technology and dramatically improved operability. Also, when vertical TGA was the mainstream, we developed a more stable horizontal differential balance TG/DTA and it’s now widely used in the world. In 2010s, we were the first manufacture in the world to develop a sample observation RealView® STA that allows to see what is happening during measurement.

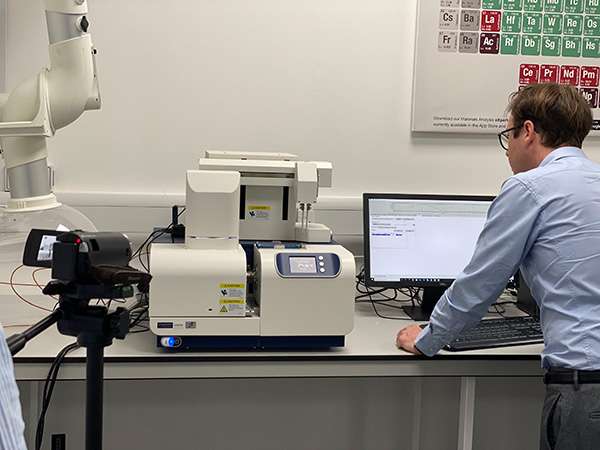

Our Real View® camera really sets us apart and makes us unique. Integrating seamlessly with our DSC, STA and DMA today to observe changes in the sample status during analysis in real-time. Images reveal changes in sample shape, size, color, and other properties. The images can be recorded and are automatically linked to the thermal data by timestamp. You can also integrate Real View® with the auto sampler to monitor changes to your samples while automatically analyzing several samples at once.

Also, our software, with ease-of-use interface and a guidance function enables measurement in accordance with standards such as ISO and ASTM. All our software is included as standard on our instruments, and comes with unlimited licenses so that you don’t have to complete the analysis next to your instrument, this can be done anywhere on your personal laptop.

We continue to work with our customers to innovate, ensuring our customer’s voice is embedded in our manufacturing process and high technological capabilities that achieve world-class sensitivity and baseline stability.

We have more than 20 applications labs globally including Tokyo (Japan), Osaka (Japan), Shanghai (China), Abingdon (UK), Kalkar (Germany), Mumbai (India), and Dallas (USA). Our labs are equipped with thermal analysis instruments with our experts carrying out hundreds of measurements and demonstration each year for customers.

Our experienced application engineers also handle a wide range of inquiries and consultations from customers such as measurement conditions, data interpretation and measurement techniques. Our teams are also equipped to deliver online demonstrations so it doesn’t matter if you can’t come to us, we can come to you and equally demo using your samples if they are sent to us in advance.

You can also find the technical data that introduces application examples here.

Responsive worldwide support minimizes your downtime, keeps your costs down and ensures you always get the best performances from your instrument. When you buy Hitachi, you get support and training from installation through tot end-of-life. Our expert service team works with your business to drive growth and get the most long-term value from your investment.

We offer extended warranties, repairs, remote support, consumables, recertification, and rental equipment. Our service agreements are created to work around your needs. From helpdesk to replacement parts and computer cover, you can pick a service agreement that ensures you only pay for what you need.

We also offer specialized training that’s designed to suit your needs. Our expert team can provide training on-site, your employees can visit one of our global training centres or it can be done online.

Our service team is always on hand to help to keep you running.

Our range of thermal analyzers have an unsurpassed level of baseline stability, world-class sensitivity and advanced capabilities to give you the complete picture of thermal behaviour. They are optimized to detect minute changes within a wide range of materials, whether you are measuring thermal expansion, thermal decomposition, specific heat capacity or determining the glass transition of polymers.

Book a demoYou might also be interested: