See more, measure more, and save valuable time.

The Dynamic Mechanical Analysis (DMA) technique enhances sensitivity in measuring glass transition, material stiffness and the impact of frequency on mechanical traits. It gauges the viscoelastic properties of materials. Reliable for product engineers in applied research and materials development, DMA analyzers offer precise measurements of mechanical properties for simple and complex materials.

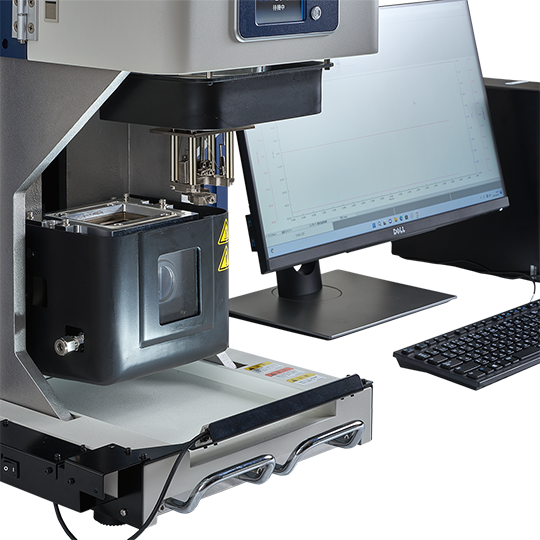

Our DMA features an innovative Real View® camera system that offers real-time observation during measurements, aiding in understanding unexpected behaviors like sample damage or color shifts. It also ensures the verification of data point reliability, even after the measurement process is concluded. And, with its exceptionally wide measurement range and rapid electronic response, our DMA is the perfect tool for assessing both stiff and soft samples, while also capturing rapid modulus changes.

Request more informationThe Real View camera system integrates seamlessly with the DMA200 to observe changes in the sample status during analysis in real-time. High-resolution Images reveal changes in sample shape, size, color, and other properties. The images are recorded and automatically linked to the thermal analysis results by timestamp, simplifying image handling and enabling easy sharing capabilities.

Enhance efficiency and reduce user errors with our automated measurement entry. Utilize a barcode reader to input essential details such as name, method file, and lot number, making data management easier and more reliable.

Deformation Mode Options | Tension, single/dual cantilever, 3-point bending, shear, film-shear, compression |

Maximum Force | 20N |

Modulus Range | 103 to 1013.5 Pa |

Frequency | Sinusoidal wave oscillation: 0.01 to 200Hz, max 20 frequencies Synthesis wave oscillation mode: 5 frequencies |

Measurement Range | 105 to 1012Pa(Tension), 105 to 1012Pa(Dual-Cantilever Bending), 103 to 109Pa(Shear), 104 to 1010Pa(Film Shear), 105 to 109Pa(Compression), 106.5 to 1013.5Pa(3-Point Bending) |

Temperature Range | Liquid nitrogen cooling -150 to 600°C Electrical gas cooling -100 to 600°C Air cooling RT to 600°C |

Sample Observation | Real View® ready |

Driving shaft | Spring mounted (no compressed air required) |

Sensor | LVDT |

Dimensions | 420(W), x 630 (D) x 725(H) mm |

*Deformation modes "Bending", "Shear", "Film Shear", "Compression" and "3-Point Bending" are optional.

We’d love to hear from you! Contact us if you would like a quote, demo, or if you have a question.