Spark mobile optical emission spectrometers (OES) excel at providing full chemistry of critical alloy elements at low detection limits that handheld X-ray and LIBS analyzers can’t: carbon, phosphorus, sulfur, boron, arsenic and tin in low alloy and stainless steels, and nitrogen in duplex steels.

That’s why spark OES is the most trusted and widely used method for creation and verification of MTR’s (mill testing reports) in the world. Our mobile and portable spectrometers also meet the world’s most stringent PMI metallurgical alloy chemistry testing requirements including API 5L testing, API RP578, ASME section IX B& PV, and ISO 17025.

Contact Us

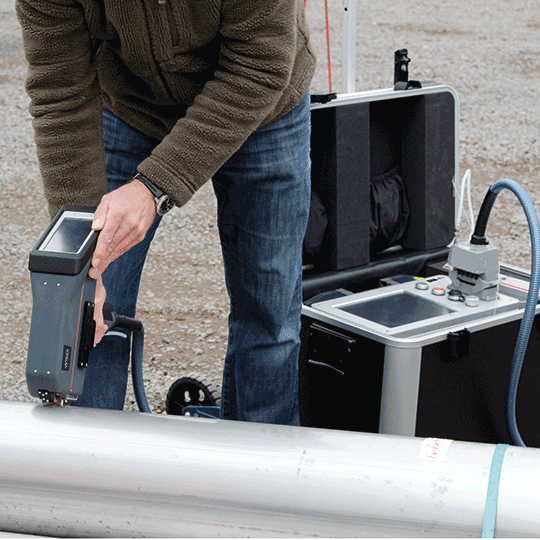

A portable laboratory giving you complete metals analysis when you need to reliably analyze steels and other alloying materials like aluminium, nickel and copper especially in PMI Safety Inspection.

Ultimate mobile metals analysis when you’re trying to prevent grade mix-ups of incoming and outgoing materials, conduct material verification and quality control or maximize profits in a scrapyard.

| PMI-MASTER Pro2 | PMI-MASTER Smart | |

| Identification of low and medium alloyed steels by Carbon content | ✔ | ✔ |

| L GRADE separation for stainless steel | ✔ | ✔ |

| Identification of duplex steel grades via nitrogen content | ✔ | ✔ |

| Battery operation | ✔ | ✔ |

| Operation via main power | ✔ | ✔ |

| Optional automation interface for integration in to inline process for 100% testing | ✘ | ✘ |

| High sample throughput | ★☆☆ | ★☆☆ |

| Precise analysis of UV elements such as P,S,B,Sn,As... | ✔ | ✔ |

| Cordless on site PMI inspection | ★★☆ | ★★★ |

| Sorting for scrap and recycling applications | ✔ | ✔ |

| Analysis of difficult sample shapes (wires, small parts, curved surfaces…) | ★★★ | ★★★ |

| Manufacturing QC/QA | ★★★ | ★★★ |

| Extension of calibration possible | ✔ | ✔ |

Our mobile spark OES analyzers come with the world’s largest metal database already installed. With more than 15 million records for over 420,000 materials from 82 countries, you’ll have easy access to the information you need with no time-consuming research in norms and grade catalogues.

Upstream

Material verification both on and offshore.

Midstream

Pipeline safety asset verification with full chemistry measurements.

Downstream

PMI for components before, during and after use, including welds.

Power Generation

PMI for components that meets ASME Section IX B&PV code standards and FAC analysis.

Automotive/Aerospace

Incoming inspection to ensure integrity of material used.

Fabrication

Analyze and identify material grade and alloy composition.

Metal Production

Scrap sorting and final compositional verification check.

Other Plants

Verifying materials for weldability, providing a library of CE and other formulas.

Watch Steve Baldwin, Technical Director at PTS TQM Ltd, explain why they have invested in Hitachi analyzers.

We’d love to hear from you! Contact us if you would like a quote, demo, or if you have a question.