Setting up a measurement with an XRF (X-ray fluorescence) coatings analyzer involves several steps, with the focusing aspect being the most crucial. The geometry between X-ray tube, part, and detector significantly affects the result of accuracy.

Once the operator located the measurement location, they use laser focus or video focus to achieve proper focus on the part. Although the FT230 Series coatings analyzer can use a focus laser, they also employ automated focusing features to make the process more efficient.

Precision in one click

There are two features; auto approach and auto focus. Auto approach measures the distance from the X-ray tube to the part and automatically drives the tube to the predefined working distance. Auto focus, sometimes called distance-independent measurement, also measures the distance from the X-ray tube to the part, but instead of moving the tube, it keeps the tube at the same height and uses that distance to correct for the new geometry. Each approach will significantly improve your testing program's efficiency.

Auto approach explained

An XRF coatings analyzer assists when the distance between the X-ray tube, part, and detector remains constant for each measurement. X-ray intensity is a function of distance and any changes to the tube-part-detector geometry will affect thickness measurements.

One of two ways is relied upon to retain this crucial geometry: a video focus or focus laser. The benchtop analyzer's head (which contains the X-ray tube and detector) moves up or down until the instrument's focusing routine finishes. The operator may need to make some slight adjustments. Since these routines are time-consuming, operators will need to make decisions to avoid errors.

The FT200 Series includes an auto approach feature that brings the head to the right position for measuring the distance to the sample in one click. Once the auto-approach activates, it compares that distance to the working distance (also known as the focal distance), and the head moves to that position. The operator has complete confidence in their accuracy and avoids all potential mistakes.

Time efficiency in action

A simple experiment illustrates the benefits of the auto approach. Parts of six different heights, ranging from 4.8 – 6.6" (1.9 – 2.6 cm) are loaded into the chamber. The multipoint program enables the measurement of a specific location on each part.

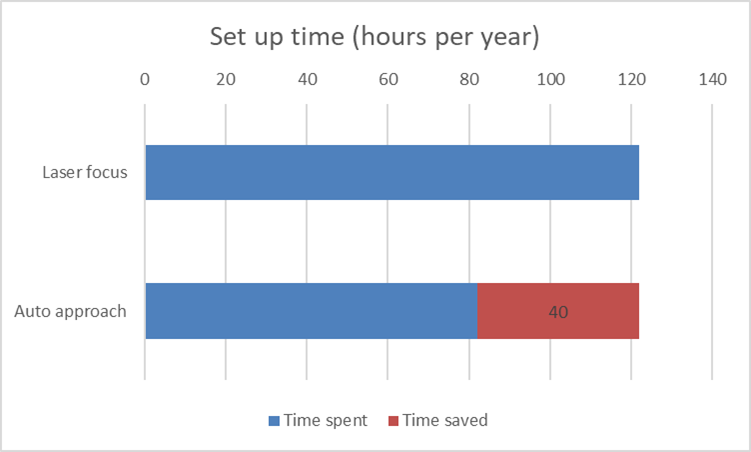

The operator runs the experiment in two ways: once with a focus laser and once with auto approach. Measurement times remain identical in both scenarios. The results speak for themselves:

6-point program utilizing the laser focus: 44 seconds

6-point program utilizing auto approach: 29 seconds

Time savings: 15 seconds (33% savings)

Fifteen seconds may not seem like much, but that is 12 minutes across an entire working day assuming the task is run 50 times. An XRF operator can create a full working weeks’ worth of additional time for themselves over the course of 200 days.

Auto focus explained

The FT200 Series incorporates an auto focus feature with practically no operator involvement and no analyzer head movement. When active, the camera automatically focuses on the part in question. The distance to the part is also measured and is taken into account in the calculations, allowing for the measurement of parts with differing heights.

Illustrating the benefits of auto focus

To illustrate the benefits of auto-focus, one can conduct a simple experiment. Six parts of heights ranging 4.8 – 6.6" (1.9 – 2.6 cm) are loaded into the chamber. A multipoint program is created by the operator to measure a location on each part.

The operator uses two methods: a focus laser (operator has focusing input) and auto focus (operator has no focusing input). Measurement time is identical in each scenario and only the setup time is considered. These are the results:

Creating a 6-point program with laser focus: 44 seconds

Creating a 6-point program with auto focus: 17 seconds

Time savings: 27 seconds (62% savings)

These numbers are significant, and when considering 50 runs per day, the cumulative time amounts to over 22 minutes. Auto focus creates over 76 hours of added productivity (nearly two working weeks) over 200 days of XRF operation.

Auto focus becomes more advantageous with a greater range of part heights. The operator can spend less time adjusting the head position. When the focus laser is used, the range of part heights is limited by the working range (aka focal distance).

The FT200 Series coatings analyzers empower operators to allocate more time and effort to various aspects of their daily routines. By streamlining operations, these benefits contribute to an immediate enhancement in overall efficiency.

Find out more Get a personalized quoteYou might also be interested: