At a very basic level, it’s because the instrument takes relative measurements, instead of absolute ones. Your instrument’s detector measures light intensities from the plasma at the sample surface. The software then compares the intensities of these spectral lines with those of known elemental concentrations and returns a useful concentration information to the user. So, an initial calibration is essential to make the instrument useful.

A recalibration must be carried out at regular intervals. It’s not possible to just rely on the calibration undertaken when the instrument was brand new. This is because spark spectrometers are made to be extremely sensitive in order to detect elements at the very low detection limits necessary to make them useful. The downside is that this sensitivity makes them subject to environmental parameters over the mid to long term and the results will ‘drift’ over time, reducing the accuracy. It’s standard practice to bring these results back into line with regular recalibration. In non-ferrous alloy melt verification, the instrument must be able to detect very low levels of elements that can be difficult to detect. Recalibration is essential to ensure your instrument remains capable of detecting these elements with accuracy.

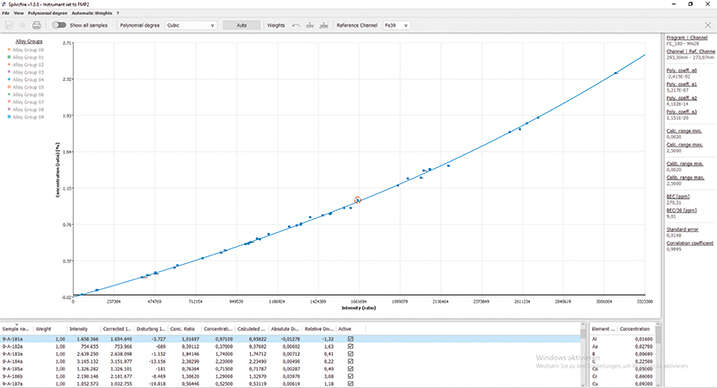

The most reliable method of determining whether you need to recalibrate your instrument is by measuring control samples. These are samples of known composition that you use to check that your analyzer returns the right results. Newly prepared control samples should be measured at least ten times and the average and standard deviation noted. It’s important that control samples must be similar in composition to the material you will be routinely analyzing in production.

Sometimes, despite regularly analyzing a lot of control samples, you will still see deviations in accuracy. This happens when you are working with exotic alloys that deviate from the matrix material, or when the structure of the CRM does not match the structure of your samples. In this case, you can run a type standardization. This will help improve the accuracy of your results, with one important condition:

Type standardization is only valid for unknown materials that are still similar in composition to the standardization sample. Never use this method to correct unusual high systematic deviations in your results for different materials.

It’s also important to note that type standardization is not an alternative to basic calibration. In fact, a recalibration must be run just prior to running a type standardization procedure – think of it as an additional step in the process. Like a standard calibration, type standardization relies on using reference materials or proven reliable specimens. However, in this case the reference material must be very close in composition to the sample you’re measuring, and the resulting type standardization will be right for that sample type only. You will need to run different type standardizations for every different alloy or composition you need to measure.

In our new guide Optimal non-ferrous melt control with spark OES, we go into more detail on the optimum sample-taking process and preparation techniques to get reliable results first time when verifying non-ferrous melt chemistry. Download your copy by clicking on the link above or on the button below.

Our OES experts presented their tips on non-ferrous melt control in a live webinar. If you have missed it, you can watch the recording here.

Get the guide

The challenge of melt control in non-ferrous casting

Non-ferrous melt chemistry verification: it's all in the sample