Lancaster University hosts one of the UK’s strongest university-based nuclear centers with internationally recognized capabilities. Joshua Findley, postgraduate researcher, is currently researching thermodynamic measurements of materials that will be inside next-generation nuclear reactors. He’s inherited a Hitachi STA7200 that the university bought back in 2015, which had only been used a handful of times since purchase. To get the instrument back up and running to support collecting novel data to help him publish papers and complete his PhD, he contacted Hitachi’s customer support team for help.

A multi-functional thermal analyzer

Lancaster University have an STA7200, a simultaneous thermodynamic analyzer, that combines thermogravimetric analysis (TGA) and differential thermal analysis (DTA) into a single instrument for simultaneous measurement. Their instrument, purchased back in 2015, had only been used a handful of times for TG (thermogravimetric) testing.

Before Joshua started in 2021, the DTA capabilities of the instrument hadn’t been put to the test. Joshua felt reassured that it would provide the highly precise and accurate measurements he needed as thanks to the STA7200’s high sensitivity and impressive performance for other colleagues. Joshua said, “whilst I didn’t choose the instrument myself, I was told the TG application on the STA7200 is second to none.”

Developing the next generation of nuclear power plants

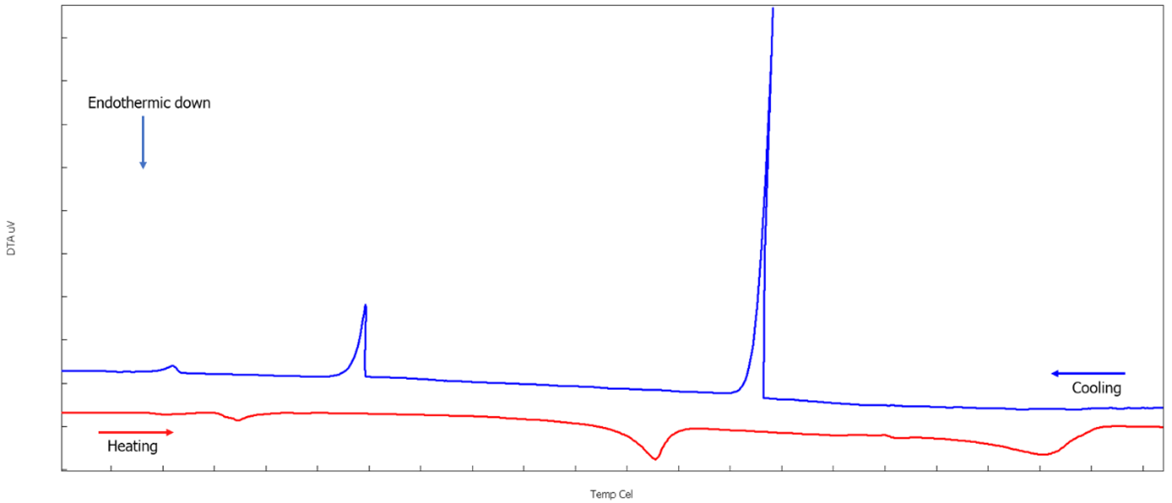

Joshua’s research involves studying the fusion of different molten salts with the STA7200 to understand their melting behaviors liquidus, solidus and solid-solid phase diagrams. The aim is to see how molten salts can be used as a primary coolant for the next generation of nuclear power plants.

The advantages of molten salts are their low vapor pressure and high boiling point which allow the reactors to work at higher temperature and lower pressure to make them more efficient and safer. A good understanding of the melting and cooling behavior of the salts is extremely important to know how effective they will be.

The STA7200 used by Joshua allows him to accurately determine at which temperature his molten salts are melting and crystallization as well as accurately measure the heat capacity of different molten salts. The thermogram in Figure 1 shows DTA results of a molten salt under controlled heating and cooling. Joshua points out, “the impressive baseline stability of the STA7200 makes my life easier when it comes to data processing.”

Being there when it matters

When the equipment failed after not being used for many years and needed repair, we were able to very quickly to send out a service engineer on-site to who was able to spot the fault within an hour. The instrument was sent to one of our repair centers to be fixed in our workshop and was returned to the research lab at Lancaster University within weeks. Our service team also ensured the instrument had the right calibration for Joshua’s work, so it provides both highly precise and accurate measurements.

Joshua added, “When problems arise, which they always do, what impressed me the most was that Hitachi’s team were available and very responsive. This was fantastic as the whole process has completely exceeded our expectations as we thought it would take months. Hitachi also arranged a courier which made everything run much smoother. This was by far the best experience the university has had with an external company with a similar situation.”

Our service team ensured any parts or accessories were quickly processed and ordered with Joshua given regular updates with useful information such as lead times and finding the quickest suppliers.

Joshua continued, “Not only has the response time and helpfulness of the Hitachi team impressed me, but Hitachi’s TA experts have also provided insightful advice which have aided the decision choices and steered my project in the right direction. This has saved me both valuable time and money from my total allowable budget. They really didn’t have to do this, to go out of their way to provide me with additional information and tips.”

NEXTA STA thermal anaylzer – visibly better thermal analysis

For over 50 years, our thermal analyzers have been counted on for reliable analysis in research and development and quality control.

Our latest STA analyzers combine DSC, DTA and TGA technologies making them a long-standing popular choice for research groups and institutions who need to fully understand the materials they are working with. They also allow heat capacity measurements up to 1500C with the standards three curves method or with modulated DSC. Our latest STA analyzer, the NEXTA STA, builds on the success of previous models and allows you to detect minute weight changes over a wide temperature range, ensuring the material meets performance and quality standards needed.

Keeping you running

Our global network of service hubs offers a full range of technical support to keep you up and running. From repairs, recertification, and maintenance to training to help you get the most out of your instrument, our specialist team are on hand to help. We also offer consumables and accessories so that you can feel reassured that you are using the genuine parts needed for your analysis.

A range of content from tutorial videos to answers to frequently asked questions is also available on the service part of our website to enable you to fully understand your analyzer.