Businesses like yours are looking to ensure they don’t have any waste when it comes to plating and surface finishing. Too thick, and mechanical fit may suffer while money is wasted on excess material. Too thin, and products may not meet performance targets so businesses face downtime and costs correcting mistakes.

In the worst cases, they may find their reputation tarnished when products fail. By regularly checking their output, businesses can ensure they minimise their waste and the downtime caused by having to scrap or rework products.

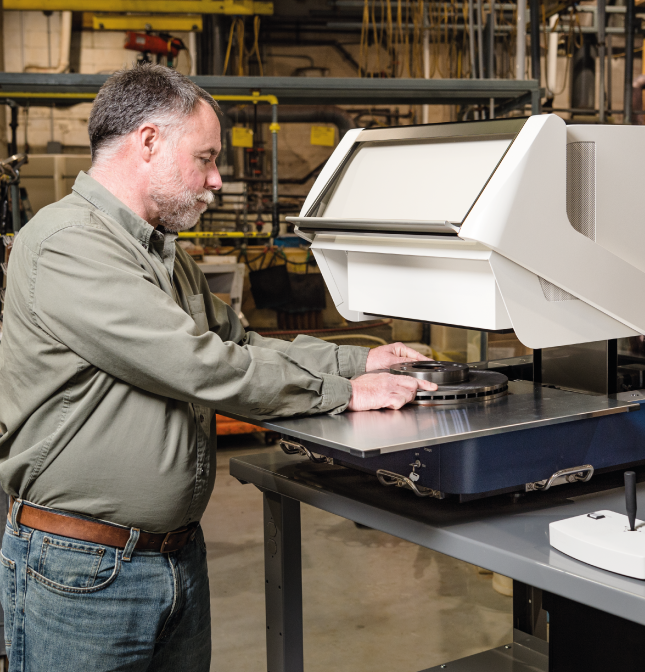

For this reason, choosing the right equipment to analyze coatings is extremely important for your business. Many companies who analyze coatings choose XRF because it’s non-destructive, fast and straightforward. XRF instruments come in many forms with features that determine how appropriate they are for your application. Two key things you should consider when choosing your equipment is the type of detector and the size of sample you measure:

Choosing the right detector can give you shorter measurement times to improve testing throughput and offer better flexibility to make the analyser as productive as possible.

To measure coatings on small features, XRF coatings instruments use either a proportional counter (PC) or a silicon drift detector (SDD).

Proportional counters are good for many coatings applications, but are best when there are few elements present in the sample and when measuring thin coatings on small areas.

SDD’s more easily handle complex coatings structures because of their superior resolution; SDD’s can also be better for very thin coatings (<0.05 um). Something to consider is how much flexibility you need in your business. SDD’s offer better flexibility for future needs and can better handle changes such as alloy coatings, adding a new intermediate layer, or changing the base metal. Cost is also a consideration - SDD’s cost more up-front but may be more future proof and save money in the long run.

Image credit: F.M. Callahan

Considering the samples you measure and the way you measure them will impact which analyzer is suitable for your application.

Sample size is an obvious thing to consider when choosing your analyzer. Beyond simply whether or not your samples will fit, consider whether or not the analyzer you buy will be future proof. Choosing a coatings analyzers with the right features can improve productivity for measuring samples today, and adapt to changes in the parts you plate and the markets you serve. This extends the life of the XRF instrument and gives you more opportunities to win new business.

Your sample shape will heavily influence the kind of analyzer you buy. Long and skinny samples are better suited to slotted chambers because they can slide through the opening between the stage and the door. With a slotted chamber you can move the sample along without having to open and close the instrument repeatedly. However, a closed chamber reduces the risk of your sample being bumped during measurement - which will give you inaccurate results. Bulky samples with complex geometries work well in a closed chamber.

XRF analyzers with larger chamber may have additional features that save time. For example, larger chambers can come with dual camera views for easier movement around a sample or the ability to quickly adjust distance from the sample for parts of different heights. For some businesses automatically positioning samples is paramount to the operation because it frees the operator to perform other tasks whilst the XRF is taking measurements. For others, manually positioning the sample is sufficient.

Whatever your needs for an XRF analyzer, Hitachi High-Tech Analytical Science has the right analyzer for your business. Choose between our benchtop FT Series, X-Strata920 and handheld X-MET8000 to measure coating thickness. Contact us today for more information.