Oxford, December, 2023 – Hitachi High-Tech Analytical Science, a Hitachi High-Tech Corporation wholly owned subsidiary engaged in the manufacture and sales of analysis and measuring instruments, has expanded its coatings and materials analysis range with the launch of the new FT210 XRF analyzer.

The FT210 includes a proportional counter detector for routine measurements of common platings, and incorporates advanced user-friendly features designed to enhance high-volume testing needs.

The launch of the FT210 also includes an updated version of FT Connect software for all FT200 Series models, with enhanced usability features for reporting, creating calibrations and data handling. This new version of FT Connect expands the RoHS screening capabilities of the FT230. FT Connect V1.2 software is compatible with both new and existing instruments.

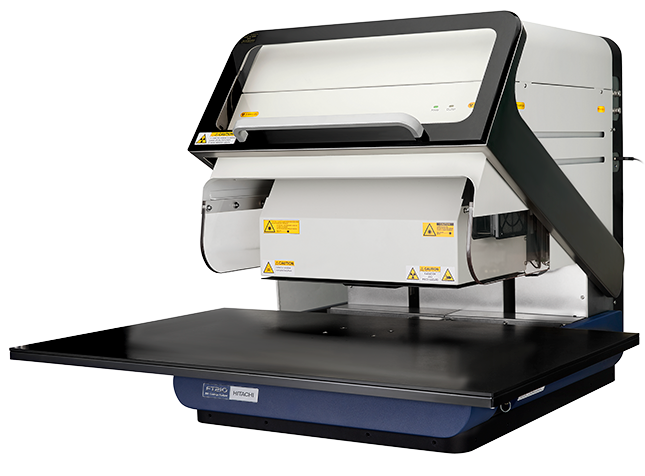

Hitachi FT210 XRF analyzer

The FT210, much like the FT230, includes features to improve productivity by reducing the time needed to set up a measurement and act on data. To accelerate analysis set up, the FT200 Series comes with the largest-in-industry sample view, wide view camera, auto-focus and auto approach, and a smart recognition feature called Find My Part™, which automatically recognizes features to be measured and chooses the correct analytical method.

New FT Connect software updates mean that the FT230 can now be used to check more materials for conformity to the latest hazardous substance directives. The RoHS screening capabilities are built into the FT Connect’s market-leading interface ensuring analysis is simple and seamless.

Matt Kreiner, Hitachi High-Tech Analytical Science’s Coatings Analysis Product Manager, said, “The FT210 offers our customers the ability to choose the best detector for their coating applications. Thanks to the introduction of the new software features, we’ve continued to innovate on how operators interact with an XRF coatings analyzer to increase testing volumes by simplifying setup and reducing the potential for mistakes. By using either the FT210 or the FT230, XRF owners can gain up to 45 minutes of operator time back per day to focus on value-added tasks or to increase testing volumes.”

From simple plating and coatings to sophisticated applications on the smallest features, Hitachi High-Tech’s extensive range of analyzers – now including the FT210 – is designed to confidently measure coated parts throughout production, from incoming inspection, process control through final quality control.

*Set-up time decreases from 73 seconds to 19 seconds for a 5-point program using Find My Part™. This saves 54 seconds per run and 45 minutes daily (with 50 runs).

Find out moreMarketing Communications Manager | Region: EMEA

Product Manager | Region: Americas

Marketing Communications Manager | Region: Asia

Marketing Communications Manager | Region: China

Head of Global Marcomms | Region: Global