In the polymer industry, manufacturers face challenges in identifying small features such as contaminations. These impurities, although minute, can lead to defects in final products, impacting quality, reliability, and customer satisfaction. Therefore, pinpointing and rectifying these contaminations is crucial for maintaining product integrity and reputation in the market.

Here, we delve into three critical aspects: fish-eye contamination detection, single-layer identification within laminates, and crystal growth studies. These areas are examined through advancements in polarization microscopy combined with differential scanning calorimeter (DSC), offering precise analytical capabilities to ensure product quality and reliability.

In electronics, manufacturers grapple with identifying tiny contaminations, known as fisheyes, within polymer matrices. These minuscule defects, often as smaller than 50µm, can lead to critical issues in devices such as smartphones.

They tend to be caused by small impurities or inhomogeneous mixtures within the production line that are making their way through the final products if these lines are not cleaned properly. Identifying the root cause of this problem is essential in correcting it. Spectroscopy techniques such as infrared or Raman microscopes have been used, but since the material causing the fisheyes is often the same as the base material, it cannot not be identified by its spectroscopy signature. Using a microscope with a hot stage is another option, but sample temperature inaccuracies may lead to unreliable results.

Developed in collaboration with smart screen manufacturers, Hitachi High-Tech has developed a polarization microscope to enhance its Real View® camera system.

This is a high-resolution microscope, with a pixel resolution of 1.2µm, featuring two controllable polarization filters for optimal contrast and material anisotropy study. Combined with our NEXTA DSC series – with exceptional sensitivity, baseline stability, temperature accuracy, and precision – it offers the best of both worlds.

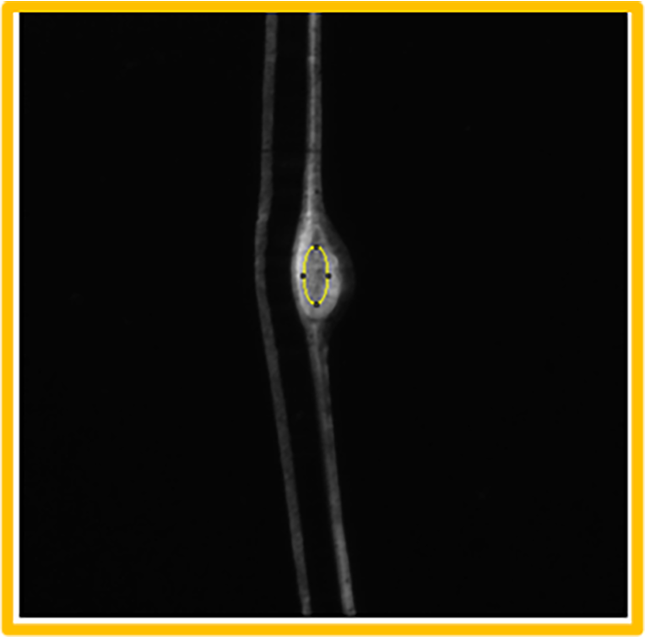

Image of visible fish-eye inclusion

As mentioned, detecting fish-eye contaminations is crucial for identifying the root cause of issues. While one method to identify them is by their melting point, DSC techniques fall short as these defects are too small to be detected.

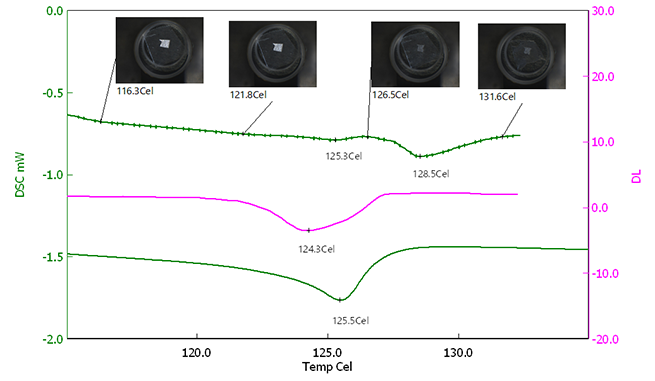

Using the Real View® Polarized Micro Sample Observation Unit for NEXTA® DSC Series in the example below, the system accurately measures the melting temperature of a specific area within a laminate, aiding in identifying the material causing the fish-eye defect. While the DSC thermogram (green) may not reveal any melting due to the contamination’s small size, the microscope results (red) clearly indicate it.

Measurement of the melting point (102.1C) of the material cause the fish-eye contamination in a laminate.

Polymer laminates are everywhere. From food packaging to smart screens. In industries such as packaging, understanding the composition and structure of polymer laminates is crucial. However, characterizing individual layers within these complex structures pose challenges. Traditional methods struggle to differentiate between layers, hindering efforts in reverse engineering or product analysis.

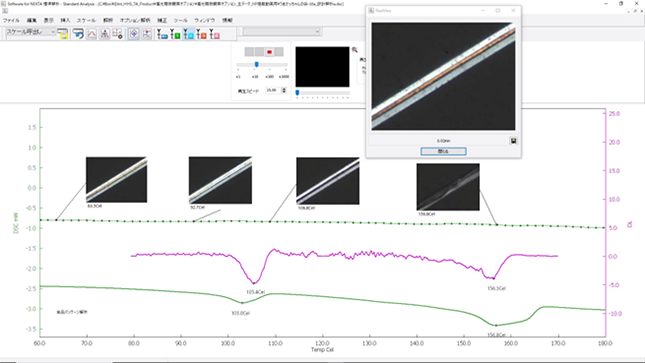

This might be done using techniques such as infrared imaging or microscopy. However, because polymers may exhibit similar spectroscopy signatures, an alternative method is often necessary. While the DSC method is commonly used to identify polymers, it struggles to distinguish between different layers within a laminate. The Real View® Polarization Microscope addresses this limitation by enabling focused measurement on each layer of the laminate, allowing for identification based on their melting points. The sample highlighted illustrates the melting behavior of different layers (pink), contrasting with standard DSC results (green dotted line) that are unable to discern individual layers due to their size. The DSC results from raw materials (solid green line) exhibit a consistent correlation with the identified layers.

Single layer identification within a polymer laminate.

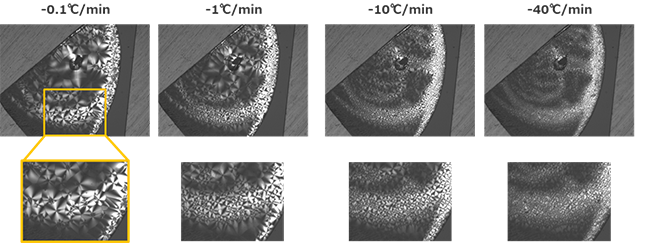

Crystal growth studies are essential in various industries, including materials science, semiconductor manufacturing, pharmaceuticals, and food science. These industries rely on understanding crystal formation processes to develop new materials, optimize manufacturing processes, and ensure product quality.

With exceptional temperature control, this accessory can also be used to study the crystallization of materials. The example shows the effect of the cooling rate on the crystal shape of polyvinylidene fluoride. By using the polarizers built-in to the microscope, we are not only able to see the effect of the cooling rate on the crystal size, but we can also see the crystal shape.

Study of crystals size and shape at different cooling rate.

While differential scanning calorimetry (DSC) is a common method for material characterization, particularly in polymer research, its effectiveness declines when analyzing small sections of a matrix, such as identifying contamination or characterizing individual layers within a multilayer sample. Standard DSC methods encounter limitations in accurately analyzing these intricate aspects of material composition and structure.

Hitachi's Real View® Polarized Micro Sample Observation Unit for NEXTA® DSC addresses these challenges, offering innovative solutions to modern analytical problems. While the examples provided demonstrate its capabilities, the potential applications of this technique are vast, offering promising avenues for future research and analysis.

Learn more about our Real View® Polarized Micro Sample Observation Unit for NEXTA® DSC.

Learn more