Typically, XRF analyzers come with one of two types of detector: proportional counters or semiconductor-based detectors. Of the semiconductor devices, the silicon drift detector – or SDD – is generally considered the best.

If your instrument has a proportional counter, you may be really happy with your analyzer’s performance; for certain applications the prop counter is just right for the job. But there’s a reason that SDDs exist, and they do offer advantages over the older proportional counter technology. Let’s take a look at a few of those advantages:

Analyse more than one element in a single scan, speeding up your analysis time.

If you are using a proportional counter to measure a sample with several elements, you might need to use a secondary filter to detect specific elements. This makes detection more accurate as the filter suppresses the X-ray signal from other elements that could interfere with the results. But, if you need results for other elements too, you might need to use several filters over the course of the measurement to get a complete compositional analysis. An SDD sees all elements at once, so fewer scans are necessary and the total measurement time is reduced.

Less frequent adjustments required to maintain results accuracy.

In simple terms, proportional counters are cylinders of inert gas that ionises when bombarded with X-ray radiation. The properties of this gas are affected by atmospheric temperature. This means that if the instrument is in a place where atmospheric conditions change widely during the day, you’ll have to re-validate or re-standardize several times to ensure accuracy of the results. Many prop counter instruments do this automatically. As SDDs aren’t affected by atmospheric conditions, they are very stable and usually provide more repeatable results.

Easier to gauge actual composition of your sample if it’s complex

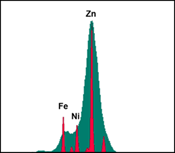

The more elements present in your sample, the more complex the spectrum becomes. The SDD gives much better resolution between elements, especially if they are near to each other in the spectrum.

This is shown in the above diagram. The red peaks show the SDD spectrum and the area in green shows the spectrum for the same sample with a proportional counter. You can see that it’s much easier to identify and gauge actual composition of iron, nickel and zinc in this sample with the SDD.

Lower detection levels mean SDD instruments cover more applications

Background levels of radiation are always present when you take a measurement. However, these background levels are usually much lower with an SDD. This makes it easier for the instrument to resolve an actual signal from background radiation. If you’re trying to detect trace elements or contaminants in the PPM range, this becomes a real issue, and for a proportional counter, variations in the background can result in a non-detect reading when there are elements present.

Overall, the modern electronics within SDDs can cope with a very high count-rate (the rate at which the detector receives and processes secondary X-ray photons from the sample). This significantly improves overall performance, resulting in better precision, lower detection limits and shorter measurement times.

Let’s look at an actual measurement by two different instruments, the Lab-X3500 with a proportional counter and the LAB-X5000 with an SDD, and compare performance. The test is to measure for six separate analytes within a single sample of limestone: Mg, Al, Si, K, Ca and Fe.

The proportional counter takes 6.6 minutes and a series of 4 conditions in total to analyse the six elements.

The SDD only takes 3 minutes seconds to analyse those same elements in a sample.

So, for this case, the LAB-X5000 is twice as fast as the Lab-X3500. And this is our experience generally when comparing proportional counter analysis time vs SDD.

There are some simple applications when a proportional counter-based analyzer is a good solution. However, you should definitely seek to upgrade to an SDD instrument if you have a high-volume facility and your XRF analysis is causing a bottleneck in production.

And it’s definitely worth checking out what SDD-based instruments can do if you need lower detection limits for tramp or trace element identification.

You should possibly upgrade if you are measuring elements that are close together in the periodic table and need better resolution to be more confident of the results.

If you are currently using the Lab-X3500, or another proportional counter instrument, then we would recommend taking a look at the LAB-X5000. In addition to the performance advantage given by the SDD, it has other features that deliver better results and can potentially reduce your analysis costs. For some applications, it can measure light elements without the need for a helium purge, and it includes automatic data export via Wi-Fi to the ExTOPE Connect cloud for flexible data management.

If you’d like to know more about the LAB-X5000, or see it in action, get in touch.

Find out more Get in touch