Foundries operate on very fine margins and need to do everything they can to increase efficiency and decrease waste and costs. Often working in high volumes, producing expensively alloyed steels, nickels and other alloys with extremely large energy requirements, operators work to very tight specifications for their end products.

In this kind of environment, melting mistakes can not only be costly but time consuming as well. When an OES analyser determines that the chemical composition of a melt or alloy does not match the desired specification, operators must perform a charge correction.

During the charge correction process, additional material is added and then the melted alloy is analysed to make sure it now hits the exact customer set specification. Doing this correctly requires a complex calculation and extensive metallurgical knowledge to choose the right source materials. Any calculation failure leads to safety risks and increased production costs.

You can avoid the risks of performing the wrong charge correction with the help of Hitachi High-Tech’s new software solutions. They take the complication out of charge correction by making it quick and flawless.

Time savings

The manual melt correction process involves three main steps:

Each of these steps increases melting time and requires a high level of analytical skills and metallurgy practice.

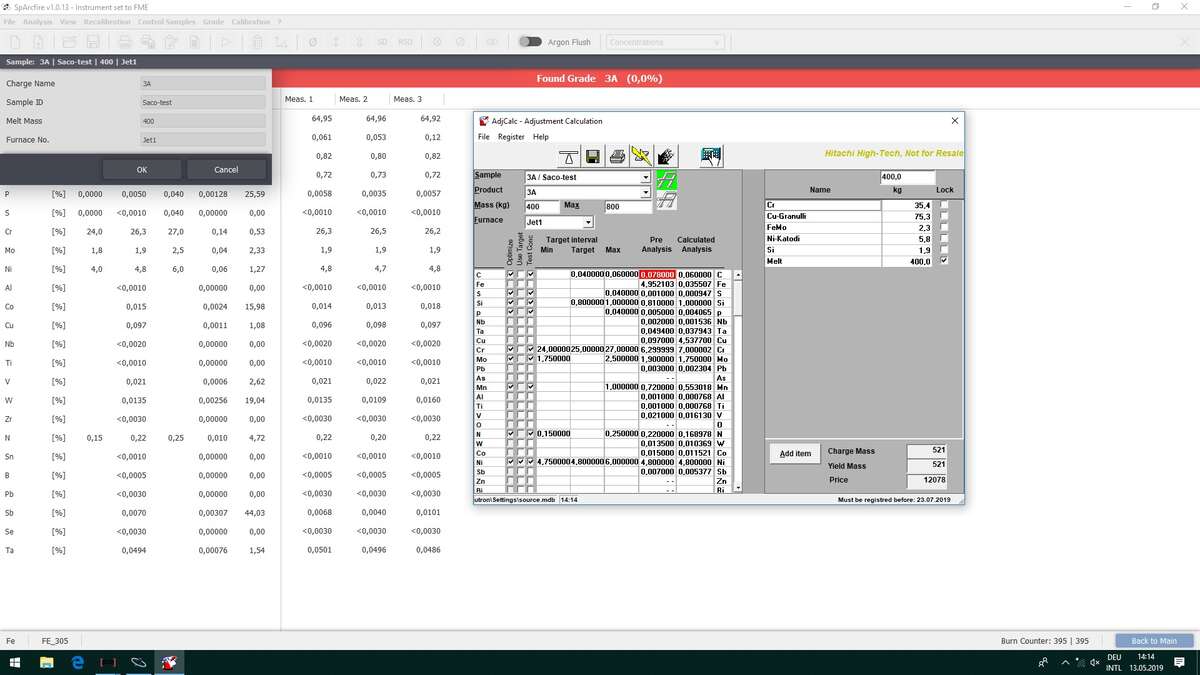

Hitachi OES combines Adjcalc software with our latest operating software, SpArcfire to enable operators to make all of these crucial decisions quickly, while also helping to add extra value. The software takes the elemental composition data from the SpArcfire software and calculates the most cost-effective way to correct the whole melt by considering the available source material and the furnace capacity. These source materials can be defined by the customer to ensure the melt can be corrected most efficiently with the available material.

Adjcalc software allows the operator to enter the price and the availability of their resource material so the computer can use this information to calculate the most cost-effective recipe. The results are then printed for the operator to acknowledge and implement. Operators can fine tune the correction by choosing how tightly to control the result. They can overrule standard specs for any special customer requirements, or relax limits, if appropriate for the particular part, to reduce the production costs.

This not only reduces your melting time, it also allows you to use additional materials from scraps instead of relying on expensive raw materials. Working alongside our extensive GRADE Database, our software solutions allow you to identify which specifications you should be using and perform charge corrections quickly, easily and safely.;

Making the complex simple

Charge correction used to be the sole preserve of operators with technical proficiency in metallurgy. Our software enables almost anyone to calculate precise charge correction. With the software doing all the work, companies can make better use of a limited number of skilled staff resources while avoiding unnecessary errors.

Fewer human errors will lead to less downtime for operators during melting and less need to divert expert personnel to the task of charge correction.

Precision and efficiency must be carefully balanced in the metal industry. By combining Adjcalc software with SpArcfire, foundries do not need to sacrifice high levels of precision to introduce cost and time savings into their processes. Hitachi’s charge correction software is another example of how we apply advanced technology to improve our clients’ operations. For over 40 years we have been helping the metal industry work faster, safer and more precisely. Taking the complexity out of a headache-inducing process like charge correction, while ensuring that the highest levels of safety are maintained, is a great example of how our solutions can add both efficiency and value to your operations.

See for yourself how easy it is to meet specification through charge correction with GIFA, 25. – 29. June, booth 11H29

For more information on how to achieve optimal melt control in cast iron with OES analysis please download our guide.