X-ray fluorescence or XRF is an analytical technique that has been used for many years to determine the elemental composition of a wide variety of materials. Examples include metal alloys, minerals, and petroleum products.

X-rays form part of the electromagnetic spectrum. They are on the high-energy side of ultraviolet, and are expressed in terms of their energy in kiloelectron volts or wavelength in nanometers.

XRF can typically analyse elements from sodium to uranium in concentrations ranging from parts per million to high percents, in solids, liquids, and powders.

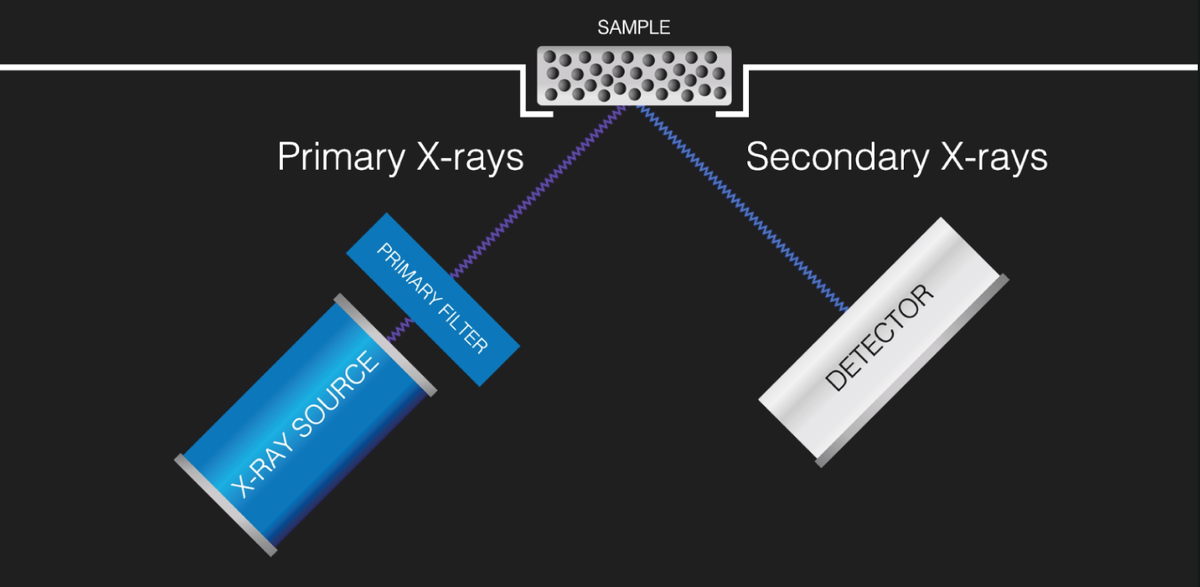

All XRF instruments are designed around two major components, an X-ray source, commonly an X-ray tube, and a detector. Primary X-rays are generated by the source and directed at the sample’s surface, sometimes passing through a filter to modify the X-ray beam. When the beam hits the atoms in the sample, they react by generating secondary X-rays that are collected and processed by a detector.

A stable atom is made of a nucleus and electrons orbiting it. The electrons are arranged in energy levels or shells, and different energy levels can hold different numbers of electrons.

When the high-energy primary X-ray collides with an atom, it disturbs its equilibrium.

An electron is ejected from a low energy level and a vacancy is created, making the atom unstable.

To restore stability, an electron from a higher energy level falls into this vacancy. The excess energy released as the electron moves between the two levels is emitted in the form of a secondary X-ray. The energy of the emitted X-ray is characteristic of the element.

This means that XRF provides qualitative information about the sample measured.

However, XRF is also a quantitative technique.

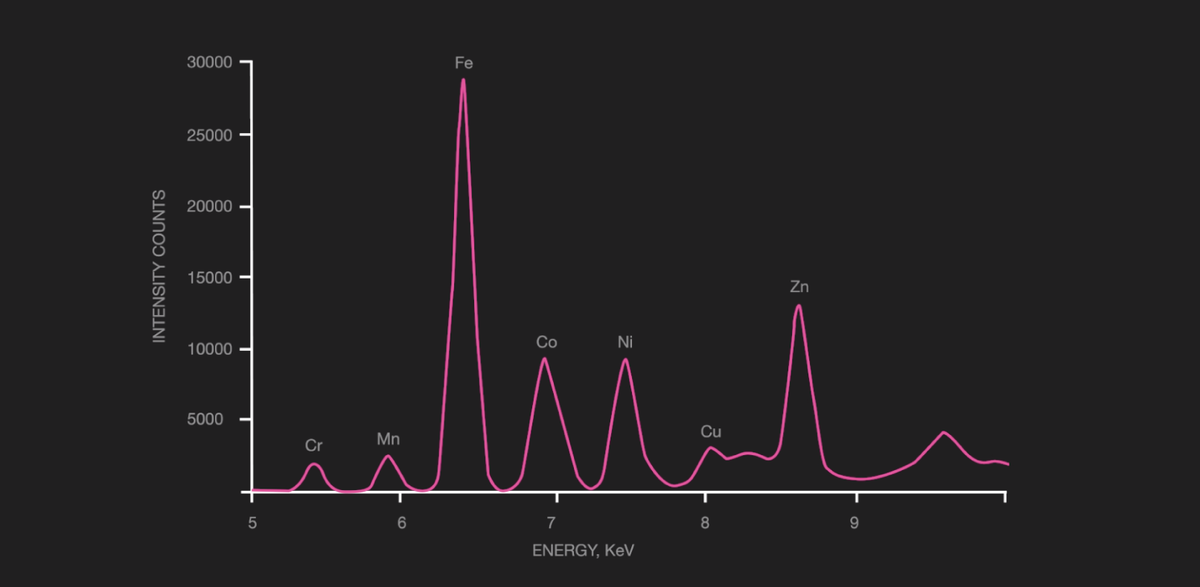

The X-rays emitted by the atoms in the sample are collected by a detector, and processed in the analyser to generate a spectrum showing the X-ray's intensity peaks versus their energy.

As we have seen, the peak energy identifies the element. Its peak area or intensity gives an indication of its amount in the sample.

The analyser then uses this information to calculate the sample's elemental composition.

The whole process from pressing a start button or a trigger, to getting the analysis results, can be as quick as two seconds or it can take several minutes.

Why do people choose the XRF technique?

Compared to other analytical techniques, XRF has many advantages.

It's fast. It measures a wide range of elements and concentrations in many different types of materials. It's non-destructive and requires no or very little sample preparation, and it's fairly low-cost compared to other techniques.

That's why so many people around the world are using XRF on a daily basis to analyse materials.