When choosing analytical equipment to support your high-quality production, you need a supplier you can rely on. Both in terms of providing reliable equipment and experts, who can answer your questions and work with you to make sure you are using the right techniques for what you’re looking to achieve. We’ve been working in close collaboration with customers for their materials analysis needs for 50 years across a range of different industries, developing customized testing methodologies for hundreds of industrial applications. Our applications and product experts are always on-hand to work with you to on how we can best meet your analysis challenges.

Recently we had a customer who works in the polymers industry ask us the following question:

We want to introduce recycled plastic in our production. How can we make sure we are using the right raw materials?

We put this question to our thermal analysis product manager Olivier Savard, who was very happy to explain some of the techniques and instruments that would be best suited to working with recycled plastic and maintaining high quality standards.

Olivier gives a brief answer to this question in the video below and introduces a few of our instruments that help with qualifying materials and determining contaminants and additives levels.

Using differential scanning calorimetry (DSC) to confirm you have the right type of polymer

A differential scanning calorimeter (DSC) is the ideal instrument for easily confirming that you have the right kind of polymer and whether it’s mixed with any other polymers such as polyethylene (PE) mixed with polypropylene (PP).

Like most materials, polymers exhibit different thermal properties when heated or cooled. Some polymers will have one melting point, while others will also have a glass transition and/or a re-crystallization point. These properties are specific to each polymer depending on their type, how they have been synthesized or which additives were added during their production.

Being able to accurately measure at which temperature and how much energy is needed to make them go through these thermal transitions is a practical way to confirm their identity. This is exactly what a DSC can do.

By heating a known quantity of a polymer at a specific heating rate (typically 10°C/min) and measuring the temperature of the sample against an inert reference (typically an empty aluminum pan), a DSC detects accurately and precisely the different thermal transitions within a polymer.

Once the transitions are detected, a user can simply compare the results with what’s expected. As an example, to check if the melting temperature of a new batch of a polymer is the same as the reference. A DSC will not only allow the analysis to confirm if the polymer is correct, but it will also determine if it’s contaminated by another polymer (e.g. PP contamination within a PE sample).

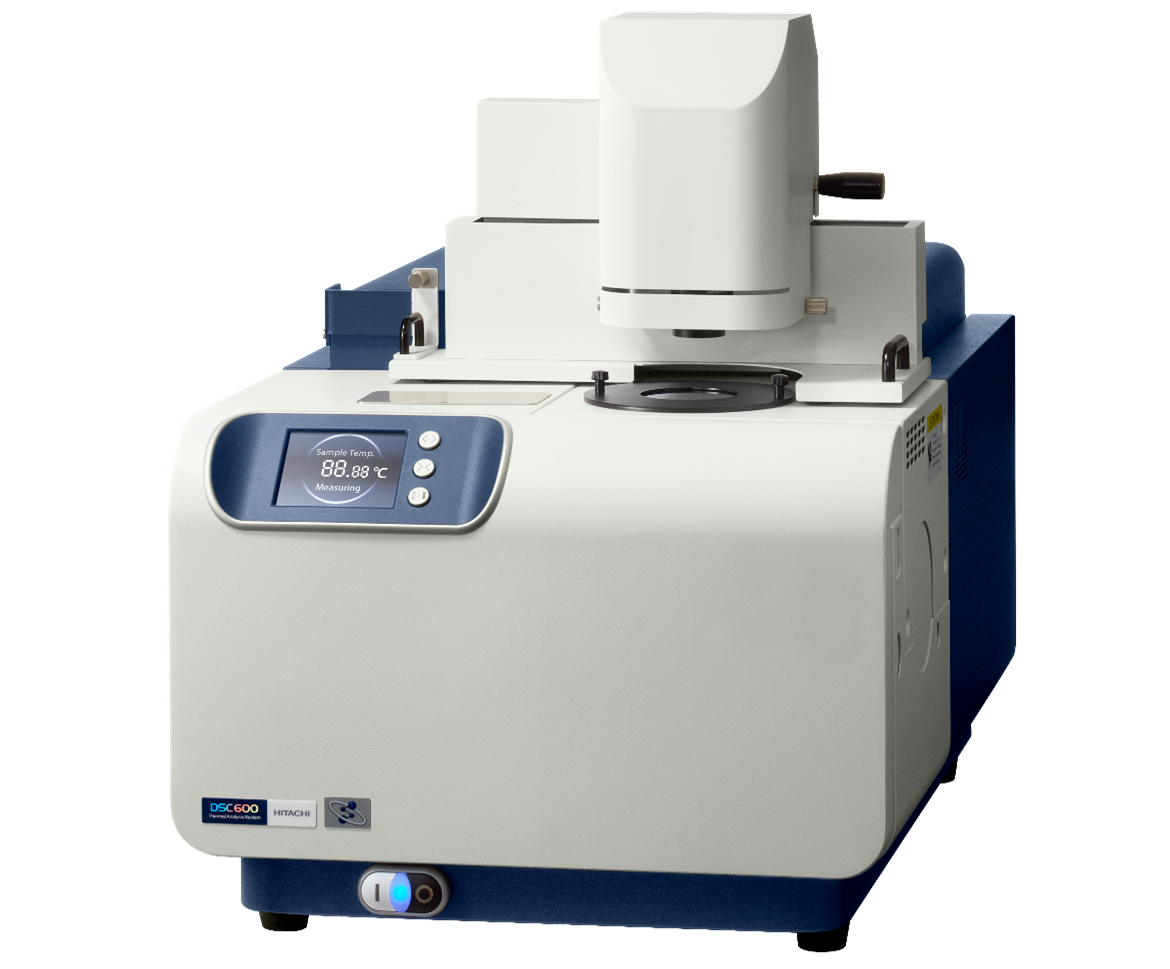

Our NEXTA DSC range is designed for accurate testing and material characterization of materials through their thermal properties such as melting points, crystallization and glass transition.

When developing new materials, the NEXTA DSC600 is the instrument of choice thanks to its high sensitivity and resolution allowing you to fully understand your material. The NEXTA DSC200 is favored for routine testing in a wide variety of applications.

Both instruments work with our Real View® camera system, which allows you to see what’s happening to your polymers in real time and gain a better understanding of your material.

NEXTA DSC thermal analyzer

To learn in more detail about how the NEXTA DSC range works for polymer analysis, please see the following application notes:

Using thermogravimetric Analysis (TGA) to judge the levels of additives in your polymers

Thermogravimetry (TGA) will give you compositional analysis, so it’s a popular technique for finding out polymer purity and how much additives such as plasticizers, pigment (e.g. carbon black or titanium dioxide (TiO2)), and inorganic content are present in your materials. It can also give important information on the amount of UV stabilizers and antioxidants.

Like most materials, different polymer types and their additives will evaporate or decompose at different temperatures. When going through these transitions, the polymer will lose weight proportionally to the amount contained in the sample which will allow the quantification of each component. Being able to quantify these weight losses and therefore quantify the amount of each component present in a material is done with a TGA.

By heating a known quantity of polymer at a specific heating rate (typically 10C/min) under controlled atmosphere (nitrogen or air), a TGA can accurately and precisely control the temperature and measure weight loss. As most materials will have their own degradation pattern, the TGA will be able to quantify how much of each ingredient is in the polymer.

As an example, the ingredients in a rubber filled with oil extender and carbon black can each be quantified by TGA. The oil will come out first, followed by the rubber in inert atmosphere. The inert atmosphere (nitrogen) is then changed for combustive atmosphere (air) which will make the carbon black combust and allow its quantification.

Since the materials need to exhibit a weight loss to be quantified, inorganic materials like calcium carbonate or titanium dioxide are difficult to measure by TGA. Non-combusting ingredients can be quantified, but these will include all materials which haven’t lost weight during the experiment. These non-combusting materials are often called ash content. In order to be able to quantify each material within the ash content, other techniques like X-ray fluorescence (XRF) are used.

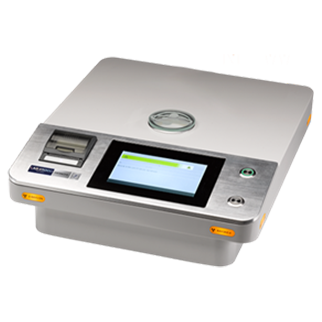

Our NEXTA STA instruments combine DSC and TGA measurement simultaneously in the same instrument with the two techniques giving you a fuller picture of your materials and any contaminants contained within them. Like the NEXTA DSC, the NEXTA STA instruments are compatible with our Real View® camera system allowing you to monitor your polymers as they are heated and cooled. The captured images alongside your results give you a fuller picture of what you are working with.

NEXTA STA200RV thermal analyzer

For a more detailed explanation and test results when using these instruments, please see the application notes below:

Identifying and quantifying inorganic fillers and other additives in recycled polymers using XRF analysis

XRF analysis can help you learn more about other aspects of the materials you’re working with, such as quantifying how much titanium dioxide is in the material. A quick and accurate technique, it’s used to determine the elemental makeup of the materials you are working with, and the results are presented on screen within seconds. This non-destructive technique allows operators to monitor the amount of catalyst residue in virgin polymers during the polymerization process.

XRF can also quantify the amount of additives such as antioxidants, antistatic agents, flame retardants, lubricants, stabilizers, pigments and fillers. With XRF analyzers, you can analyze a range of materials whether they are solids, liquids, powders, pastes, films or pellets making them ideal for polymer analysis. An XRF instrument rapidly displays results detailing the exact make up of your material.

Our XRF analyzers include the handheld X-MET8000 and the benchtop LAB-X5000 and X-Supreme8000 analyzers. These products have been designed to deliver rapid results that you can trust, and to be easy to use and fit into your operations. They’re built to be robust enough to use in the harshest production environments.

To learn more about how our XRF analyzers work for polymer analysis, please see the following application notes:

Have a conversation with our experts today

To learn more about which Hitachi analyzers can help you maintain high quality standards when introducing recycled plastic into your production, get in touch with one of our experts who will be more than happy to organize an introductory conversation or demo for you.

Find out more