A brand associated with good quality and dependable service takes years to develop and can be crucial in landing large contracts with OEMs. But that good name can be lost almost overnight if poor quality parts are allowed to enter production and pass, undetected, into consumer goods.

As manufacturers of high-quality polymer components destined for use in high performance goods, protecting your brand’s good name covers many areas. From ensuring that regulations are followed to improving in-house quality control to maintain product reliability and preventing component recall, brand protection is about ensuring the quality of your product is maintained at all times. And, apart from your production processes, this means verifying the quality, grade, composition and even behavior of the raw materials entering your facility.

There are many ways to analyze polymers for these properties, but we’re going to look at a few examples of thermal analysis as a simple, yet versatile and effective method to maintain high quality in your polymer production.

Checking incoming raw material before it hits production is essential with today’s complex supply chains and recycled material becoming more prevalent. Thermal Analysis can play a crucial role in this.

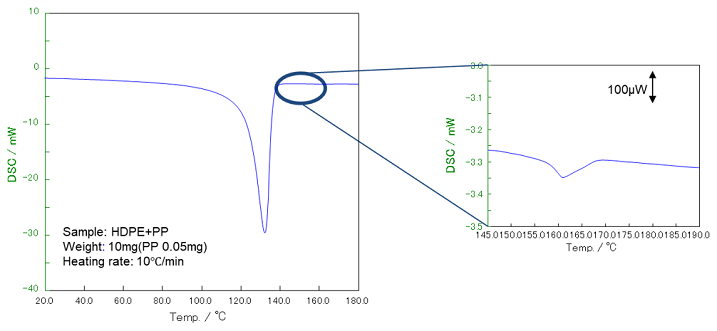

Differential scanning calorimetry (DSC) is a thermal analysis technique that detects changes of state of a substance as it is cooled and/or heated through a wide temperature range. The technique allows you to pin-point the exact temperature at which certain thermal events occur, such as the melting point or glass transition temperature. As these properties are specific to a certain polymer type, you can use this simple technique to quickly and accurately establish the polymer ID and grade.

You can also use DSC to verify the purity of recycled polymers. For example, as PP and HDPE are difficult to separate within recycling, it’s possible that PP can be mixed within the HDPE of recycled materials. As the glass transition and melting temperatures of the two materials are different, a small endothermic peak between 165ºC and 175ºC tells you that PP is present.

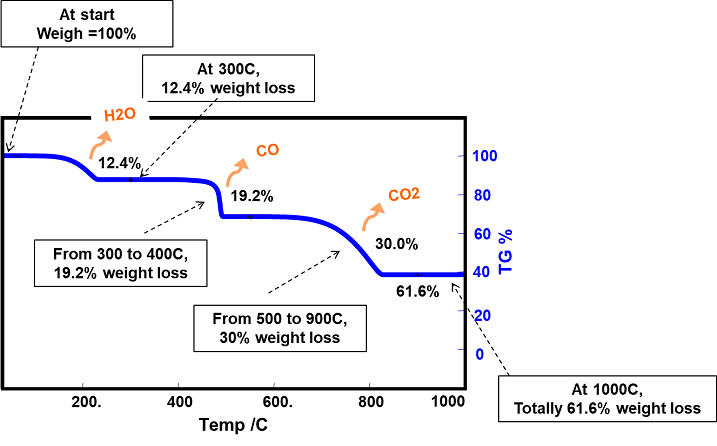

Thermogravimetric analysis is a technique where minute changes of the mass of a sample are monitored as the temperature is increased. An example of the output of a TGA measurement is shown below:

As you can see from the graph, each drop in weight at a given temperature can be attributed to the loss of a specific compound, such as water or CO. This allows you to determine the composition of the original sample. This method is useful when you are using a multi-component material, as you often are with rubber components. Another application for this method is determining the polymer coating thickness on aluminum cans.

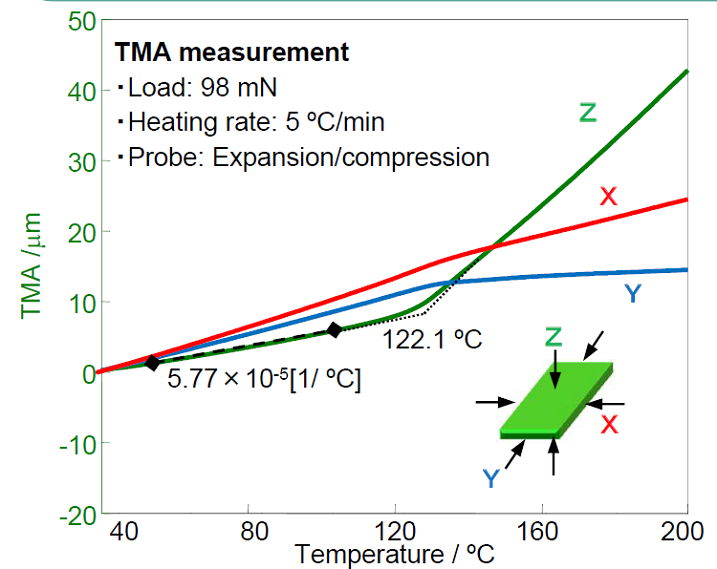

Another TA technique is thermomechanical analysis, or TMA. This method measures the thermal expansion of a component over a wide temperature range. This is especially useful when two or more materials are used in a single part, for example for printed circuit boards. Ensuring that the component parts have similar thermal expansion will prevent de-lamination during use. TMA will measure the thermal expansion and help you to determine whether there’s a danger the part will crack or separate over the normal expected temperature range of the part.

The graph above shows the result of a TMA analysis of a printed circuit board. Thermal expansion was measured in X, Y and Z directions and you can clearly see differences in thermal expansion behavior in the three directions.

Our expert in thermal analysis techniques for polymer quality control – Olivier Savard – has presented a webinar that demonstrates the techniques shown above in more detail. In this 30-minute presentation, he goes into more detail on each of the techniques and explains the results for real-world applications. On top of the examples discussed above, he also presents TA use for safety evaluation of lithium-ion batteries, demonstrates DSC results for a range of polymers and more.

After lots of interest in this topic, we created a guide on how you can protect your brand with thermal analysis of your polymers. In the guide you’ll find more detail on the different thermal analysis techniques and how they can help you maintain high standards in your production as well as guidance of interpreting results for common ASTM method measurments.