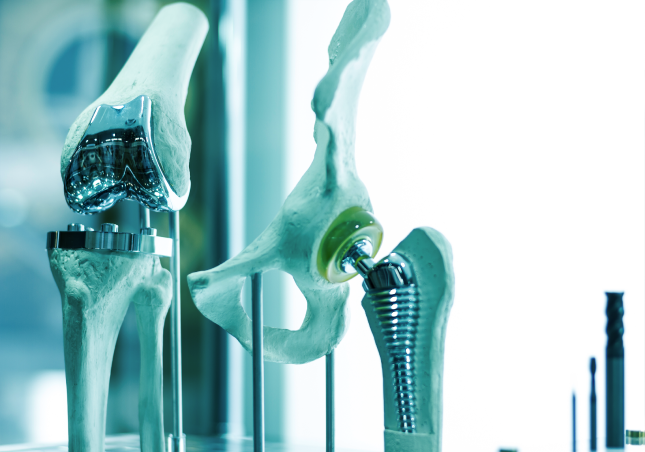

The medical implant market is expected to grow to $116 billion USD by 2022. One of the fastest growing sectors of the market is orthopaedic implants, where devices are implanted into the body to replace or support damaged bones or joints. New innovations in this area, plus an ageing population, are increasing demand for these types of implants. And these devices are coated to help them perform better.

Devices designed for use inside the body are coated for several reasons, including strength, sanitisation, and resistance to bacteria and corrosion. As orthopaedic implants are used to replace hips and knees they are made of metal for strength and durability. Some metals cause allergic reactions and are rejected by the body after surgery. To reduce the chance of this, the implants are coated with a biocompatible metal, such as gold or titanium.

On-going research is investigating how different types and structures of surface coatings can improve the performance of bone or joint replacements. For medical implants, improved performance means they last longer, are more readily accepted by the body and promote fast healing. With bone replacements, one of the key processes of a successful implant is osteo-integration. This is where the living tissue connects with the artificial implant. The more quickly actual bone connects and integrates with the part, the more rapid the recovery and stronger the joint.

Research has found that a rough, porous titanium surface encourages osteo-integration and can help post-surgery recovery.

The method of coating used to create the porous, rough titanium coating is titanium plasma spray (TPS) coating – a type of physical vapour deposition (PVD). The process is quite specialised, but basically titanium power is deposited into a plasma jet. The extremely high temperature of the plasma melts the titanium and directs it towards the substrate. The titanium solidifies as soon as it hits the cool surface of the substrate. To get the correct surface profile specific parameters of the process are set, such as: substrate rotation rate, energy input and substrate temperature. Research into this process for a variety of implant materials is currently underway.

There are other types of PVD processes that are popular for medical device implants. These processes have been used for hip, knee and shoulder implants for many years and, like the more specialised TPS, give an extremely thin and pure coating. PVD is usually carried out under vacuum and the metal is vaporised in by a stream of electrons from an electron gun. The vaporised metal then deposits onto the substrate. Surface properties, such as thickness, are carefully controlled by the voltage, power and substrate rotation rate.

The titanium-based coatings for medical implants are extremely thin and the parts complex in shape. Therefore the best method of measuring these parts is XRF analysis. This type of measurement is fast, non-destructive and is capable of accurately measuring the thicknesses required, as long as the right type of detector is used. For very thin coatings, a silicon drift detector (SDD) gives much better resolution, and will help to ensure your coatings meet the strict specifications set by this market.

PVD and TPS are rather specialised techniques that are very different from electroplating. However, all signs show that the market for titanium coated medical implants is likely to increase substantially over the next few years, so it might be worth seriously considering adopting this new technology.

If you need advice on how to use XRF for fast and accurate quality control, get in touch. You can find product-specific information on our range of analysers here.

If you need advice on how to use XRF for fast and accurate quality control, get in touch. You can find product-specific information on our range of analysers here.

Find out more