Climate change is the single biggest environmental issue of our time and the recycling industry plays a key role in helping to combat it. To showcase the importance of recycling as part of Global Recycling Day taking place on Sunday 18 March 2018, Hitachi High-Tech’s Mikko Jarvikivi, Product Manager, looks at how our range of metal analyzers are helping to make a difference.

What is Global Recycling Day?

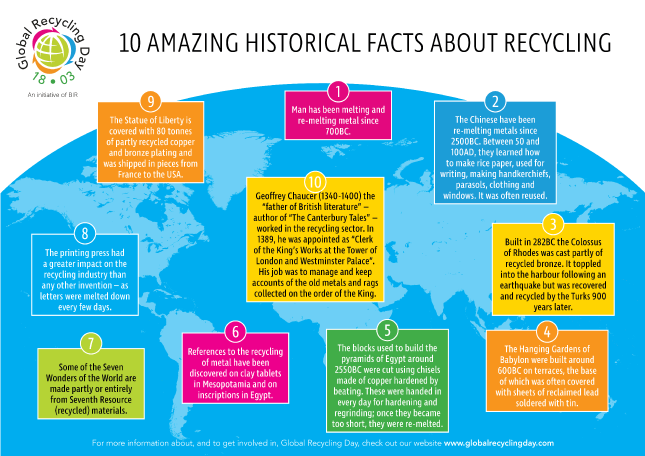

An initiative of the Bureau of International Recycling (BIR), the single biggest mission of the day is to raise awareness regarding the importance of recycling.

www.globalrecyclingday.com

Growth of the metal recycling industry

All of the metal in the world is either underground, in use in our everyday lives or in the form of scrap. Recycling metal is a cheaper source of raw material than mining, and saves a lot of energy. For example, up to 95% of energy is saved when aluminum is manufactured from scrap metal instead of refined from bauxite ore.

Metal can be recycled over and over again, and it is increasingly being used as a raw material by foundries. In a foundry, when the metal gets melted into a liquid as part of the casting process, it’s important to get the chemistry right. It’s like baking a cake; you have to get your measurements correct to make the perfect cake. So to make the perfect batter, or in this case molten mix, you need to make sure that what you put in – virgin material, external scrap, internal scrap and alloying elements – will bring the final chemistry within a specific range specified by the customer, industry and standards.

That’s why steel mills or foundries want homogenised material or material which, after smelting, has a predictable mix of alloying elements. No one wants surprises, such as harmful elements. So it’s important that scrapyards have the right tools on hand to help them to sort and analyse stainless steels, copper, nickel, cobalt, aluminum, titanium and more.

Our range metal analysers

At Hitachi High-Tech, we provide a range of metal analyzers across three technologies for the scrap industry depending on whether it’s sorting or analysis they are after.

Our handheld Vulcan laser analyzer is great for fast sorting of e.g. aluminum alloys and steels, thanks to its one second analysis time. Vulcan is also extremely robust and reliable tool, designed to be used in the most demanding environments such as scrap yards.

Our handheld X-MET XRF (X-ray fluorescence) analyzer range provides rapid analysis of virtually all solid sample types and not limited to just metals. Their FP methods makes it suitable for unknown and special alloys. XRF is the most forgiving of the three technologies when it comes to sample preparation.

Our Mobile and stationary OES analyzers provide the top level performance. They are capable of detecting very low concentrations, down to <10ppm level. They can detect carbon, nitrogen, sulfur and phosphorous in steel.

With a full product portfolio for elemental alloy analysis, Hitachi High-Tech’s instruments cover all the applications for a scrapyard from sorting to accurate analysis of trace and penalty elements. Really couldn’t get easier to make a difference on Global Recycling Day.

If you want to see our analyzers in action, visit our Booth 949 at ISRI 2018 on 14-19 April in Las Vegas or contact one of our experts for a demo today.

Learn more