Reliable, accurate and ultra-sensitive analysis is essential in ensuring polymer products that are used in industries such as electronics, consumer goods, food, pharmaceutical, and automotive are safe and reliable, and meet stringent specifications. For waste polymers and rubbers, analysis plays a crucial part in sorting them for recycling and reprocessing.

We produce a range of analyzers to help polymer manufacturers, recyclers and researchers meet increasing demands, while maintaining the highest product quality standards and RoHS directives. Our range of thermal analyzers deliver excellent baseline performance and sensitivity for materials verification and thermal behavior characterization and our XRF analyzers are ideal for compositional measurements within a polymer matrix.

Our range of thermal analyzers for polymers have an unsurpassed level of baseline stability, world-class sensitivity and advanced STA (TGA/DSC), DSC, DMA and TMA capability. They are optimized to detect minute changes within polymer matrices, while being robust, reliable and easy to use.

Product quality is crucial to the success of your business. With exceptional baseline stability and sensitivity across the range, Hitachi thermal analyzers give you uncompromised quality control and enable you to reach the next level in research and development. Seeing is believing with our unique RealView® technology, which allows you to visually capture what is happening in your furnace in real time, giving you greater insights than with standard thermal analysis data alone.

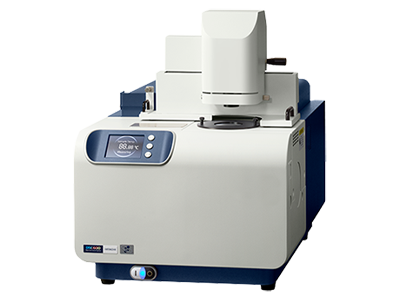

NEXTA DSC range for accurate materials characterization

Designed for accurate determination of melting point, glass transition and crystallization temperatures, the NEXTA DSC range of differential scanning calorimeters deliver excellent sensitivity and baseline flatness. This high sensitivity means that you can be confident in capturing all the critical information you need to achieve your goals.

NEXTA STA for comprehensive materials verification and thermal characterization

TGA baseline drift and stability of less than 10µg, with innovative furnace and balance design deliver ultimate precision and accuracy, even when measuring trace amounts of additives like plasticizers within your polymers.

NEXTA DMA for high performance viscoelastic analysis

With a wide measurement range and rapid electronic response, the DMA200 NEXTA DMA excels in viscoelastic analysis of polymers. Ideal for both production and research, the NEXTA DMA features the innovative Real View® camera system, enabling real-time visual observation, rapid modulus change detection, and advanced analysis. The DMA200 is ideal for production and research, featuring an innovative Real View® camera system which enables real-time visual observation, rapid modulus change detection and advanced analysis.

TMA range for polymer deformation analysis

With a wide temperature range, options for multiple furnaces and adaptable software, Hitachi’s range of TMA instruments deliver precise results on expansion and shrinking of polymers. With a complete range of modules included with the instrument, specialized analysis, such as softening point determination of thin laminated layers and coefficient of thermal expansion (CTE), is easy.

| Melting | ★★★ | ★★☆ | ★☆☆ | ★☆☆ |

| Glass Transition | ★★★ | ★☆☆ | ★★★ | ★★★ |

| Sample visualization | ★★★ | ★★★ | N/A | ★★★ |

| Crystalization | ★★★ | ★☆☆ | ★★☆ | ★★☆ |

| Reaction (curing polymerization) | ★★★ | ★★☆ | ★★★ | ★★★ |

| Sublimation, evaporation, dehydration | ★☆☆ | ★★★ | N/A | ★☆☆ |

| Thermal absorbtion / adsorbtion | N/A | ★★★ | ★☆☆ | ★☆☆ |

| Thermal decomposition | ★☆☆ | ★★★ | N/A | N/A |

| Thermal expansion and contraction | ★★☆ | ★★☆ | ★★★ | ★★★ |

| Study of thermal history | ★★★ | ★★☆ | ★★★ | ★★★ |

| Cp (specific heat capacity) | ★★★ | ★★★ | N/A | N/A |

| Dynamic viscoelasticity | N/A | N/A | ★★☆ | ★★★ |

| Evolved gas analysis | N/A | ★★★ | N/A | N/A |

| Frequency dependent event | N/A | N/A | ★☆☆ | ★★★ |

| Kinetic study | ★★★ | ★★★ | N/A | N/A |

These XRF instruments are designed for rapid analysis in a fast-paced production environment. Ideal for verifying the content of catalyst residue during polymerization, additives and fillers during the compounding process, and for incoming material verification prior to component production or industrial waste reprocessing.

LAB-X5000 benchtop XRF analyzer for fast process and quality control.

The LAB-X5000 is built to perform 24/7 in fast-paced production environments. A high-resolution detector and advanced software features allow for precise and accurate measurement of a wide range of elements.

X-Supreme8000 benchtop XRF analyzer for high-volume analysis

The X-Supreme contains a high-resolution detector and sample changer for the automatic measurement of up to 10 samples at once, making high-volume analysis easy.

X-MET8000 handheld XRF analyzer for chlorine, bromine and metal content analysis

The X-MET8000 is a ideal for checking raw polymers as well as finished products for chlorine content, to give an indication of the presence of PVC (and potentially phthalates) in the materials being used. You can also use it to determine bromine content in polystyrene waste. To separate HBCD from other brominated compounds sample preparation is needed. X-MET also makes it easy to measure metal content in plastics.

| LAB-X5000 | X-Supreme8000 | |

| Element range (elements suite depends on application) | Na-U | Na-U |

| Sample changer | No | Yes (10-position) |

| Operation | Touch screen | Touch screen and integrated keyboard |

| High resolution detector | Yes | Yes |

| Automatic atmospheric compensation (for repeatable analysis of light elements Na – Cl in air path) | Yes | No |

| Helium purge for improved performance of Na-Cl | Yes | Yes |

| One-touch to start measurement | Yes | No |

| SmartCheck software for customised analysis checks | Yes (basic) | Yes (advanced) |

| Automatic data storage | Yes | Yes |

| Cloud-based data backup with ExTOPE Connect | Yes | No |

| Factory Calibrations for selected applications | Yes | Yes |

| Sample Spinner for optimum repeatability of powders, granules and irregular shapes | Yes | Yes |

| Safety window to prevent sample leakage in the analyzer | Yes | Yes |

Contact us to find out more

If you have a question, or require a quote or demo, then please complete your details.