When it comes to metal production, fabrication and product manufacturing, we know end-to-end quality assurance and control has never been more critical to increase yield. That’s why with our metal analyzers you can simply and accurately test the elemental structure of virtually any metal at any stage of the production process – whether raw materials or finished products – in the pursuit of 100% quality.

↓ SCROLL DOWN ↓

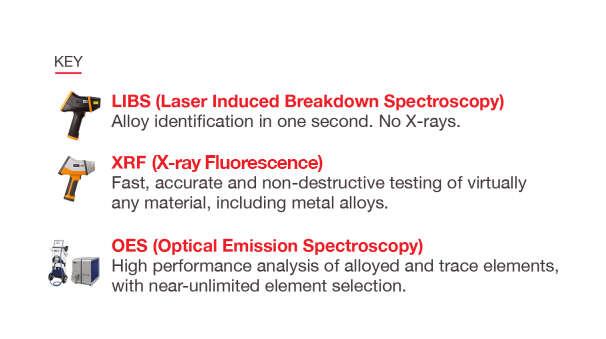

Whether your raw material comes from mining or scrap metal, meeting customer specification is vital. Our range of handheld analyzers enable effective sorting, grade control, grade ID/verification, and tramp element analysis.

Watch the X-MET8000 being used for geochemical analysis

Watch TNT Scrap talk about why they invested in a Vulcan for scrap recycling

↓ SCROLL DOWN ↓

Quality control can be a challenge during metal production. Master every melt, reduce tap to tap time, and achieve accurate metal analysis with our range of optical emission spectrometers. From verification of incoming materials to quality control before shipment, our portable and mobile analyzers help you avoid material mix-up and maintain visibility and quality over your operation.

See how our OE series could help you with process control

See how our mobile OES range can help with quality control before shipment

Watch Ninh Binh explain why the FOUNDRY-MASTER Smart is the ideal solution for their foundry

↓ SCROLL DOWN ↓

Ensuring quality during the fabrication process helps you meet compliance and cost pressures. Our range of metal analyzers enable you to verify and test the elemental composition of materials entering the process, to avoid the cost and waste of re-work. QA/QC checks when components are finished provides reassurance your products meet specification.

Webinar - How to conform with norms & regulations using material analysis equipment

Webinar - Using Vulcan Smart+ to identify alloys for PMI QC

See how our Vulcan LIBS analyser is used for QA/QC analysis

Paul Meijering Stainless Steel

Koster und Co

Schmolz + Bickenbach

↓ SCROLL DOWN ↓

Take control of your processes and make sure products are made of quality parts and exactly the right composition. Our range of material analyzers help you ensure quality and consistency in the product manufacturing stage. This includes incoming inspection, verifying component material, warehouse management, and non-destructive regulatory compliance screening (RoSH).

See how our Handheld XRF analyser X-MET8000 is used for quality control & assurance

Webinar - Understand how complimentary material analysis techniques can help improve quality

See why our XRF coatings analysis range for metal finishing can make the difference

AVID

Bunting-Redditch